Distributed Control Systems: Architecture, Functionality, and Applications

Abstract

A Distributed Control System (DCS) represents a sophisticated architectural paradigm for the automated control of complex industrial processes. Characterized by the geographical and functional distribution of autonomous controllers throughout a plant, a DCS enhances reliability, scalability, and performance while maintaining centralized supervisory oversight. This document provides a systematic introduction to DCS principles, detailing its hierarchical architecture, core subsystems, functional characteristics, and prevalent industrial applications.

1. Introduction to Distributed Control Systems

A Distributed Control System (DCS) serves as the central nervous system for modern industrial automation. It is a computer-based control architecture deployed for processes or plants comprising numerous interactive control loops. The defining characteristic of a DCS is the distribution of control functions across multiple, localized processing units (controllers) rather than reliance on a single, centralized computer. These distributed controllers are networked via high-speed communication protocols, enabling integrated monitoring and coordination while allowing subsystems to operate semi-autonomously. This design philosophy significantly improves system resilience and reduces installation complexity and cost.

2. Core Subsystem Architecture

A comprehensive DCS is logically organized into five primary functional subsystems:

- Process Interface Subsystem: Manages the physical interaction with the plant. It acquires real-time data from field instrumentation (sensors, transmitters) and executes output commands to final control elements (actuators, valves, drives).

- Process Control Subsystem: Houses the autonomous control logic. Utilizing pre-programmed algorithms and control laws stored in its memory, this subsystem processes input data from the Process Interface and computes the appropriate corrective output signals.

- Process Operation Subsystem: Serves as the primary human-system interface. It provides operators with visualization tools (HMIs), alarm management, historical trend data, operational reports, and procedural guidance, facilitating informed decision-making and supervision.

- Application Engineering Subsystem: Acts as the development and maintenance repository. It contains all software tools for system configuration, control strategy programming, display design, compilation environments, program libraries, and historical data archives.

- Communications Subsystem: The critical backbone enabling data exchange. It ensures seamless, reliable information flow among all other DCS subsystems and facilitates integration with external enterprise-level systems.

3. Hierarchical Block Diagram and Functional Levels

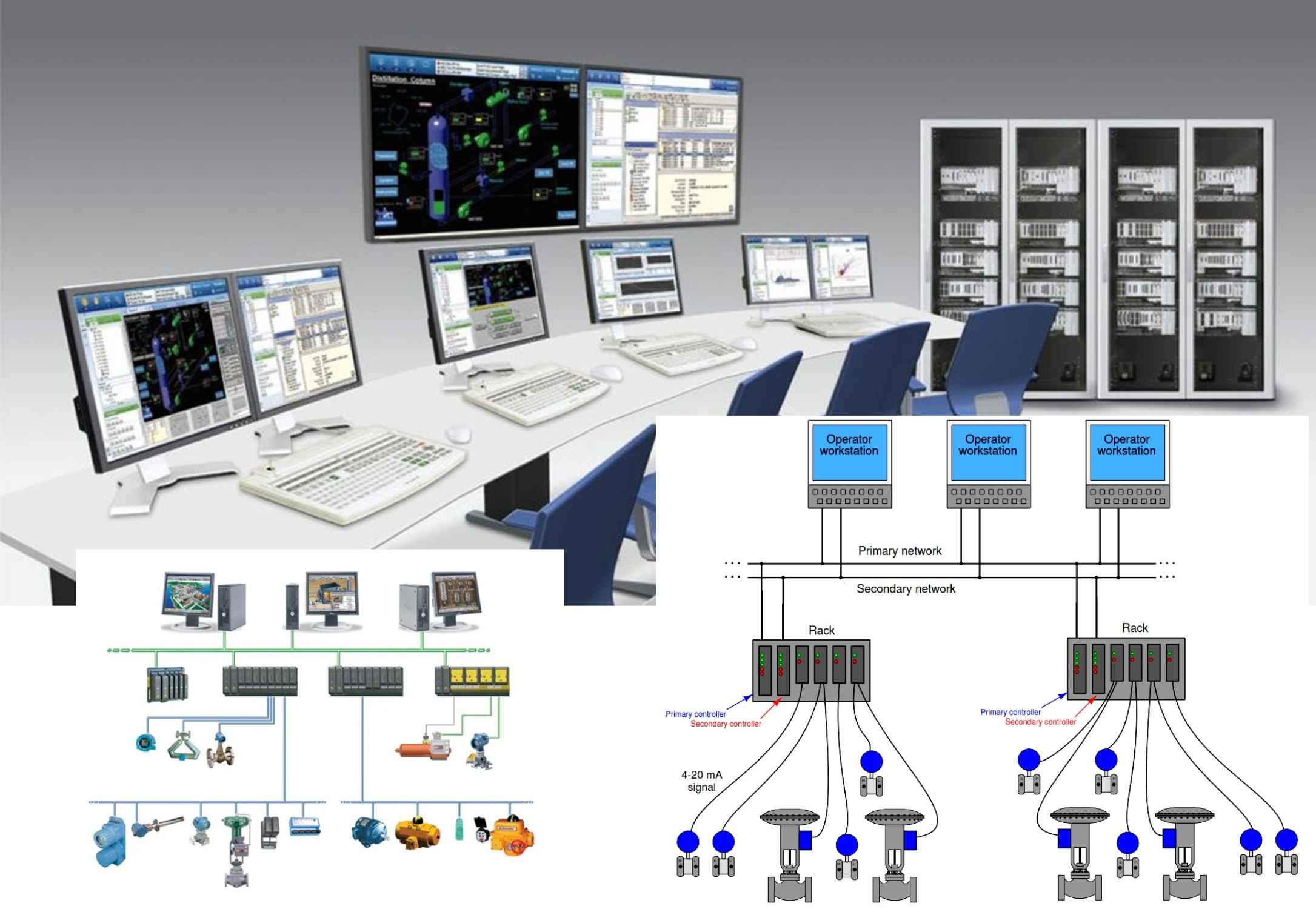

The DCS architecture is commonly represented through a hierarchical block diagram (see Figure 1), illustrating the functional decentralization of processing power. This distribution enhances overall system reliability; a failure in one controller node typically affects only its associated loop or unit process, thereby mitigating plant-wide downtime. Furthermore, locating control processing close to the field Input/Output (I/O) points minimizes network latency, ensuring rapid loop execution times.

The hierarchy is often described across several levels:

- Level 0: The field level, comprising sensors and actuators.

- Level 1: The local control level, involving I/O modules and distributed processors for direct regulatory control.

- Level 2: The supervisory level, featuring supervisory computers that consolidate plant-area data and host the primary operator HMIs.

- Level 3: The production control level, focused on plant-wide monitoring, scheduling, and performance optimization.

- Level 4: The enterprise planning level, concerned with business logistics and production scheduling.

4. Key Architectural Components

The physical and logical design of a DCS integrates several key components:

- Controller: Dedicated processors executing control algorithms for assigned loops.

- Human-Machine Interface (HMI): Workstations or panels providing graphical process visualization and operator control capabilities.

- Input/Output (I/O) Modules: Hardware that conditions and interfaces analog/digital signals between field devices and controllers.

- Field Devices: Sensors and actuators that measure or manipulate process variables (e.g., temperature, pressure, flow).

- Communication Network: A robust data highway (using protocols such as Ethernet, Profibus, or Foundation Fieldbus) interconnecting all components.

- Engineering Workstation: A dedicated terminal for system configuration, programming, and maintenance.

5. Salient Characteristics and Advantages

Principal characteristics of a DCS include the functional distribution of control tasks, integration via high-speed data buses, and comprehensive capabilities for data acquisition, presentation, and advanced regulatory control. The resultant advantages are significant:

- Enhanced Reliability: Distribution ensures that a single controller failure does not lead to a total system shutdown.

- Reduced Engineering Effort: Modular design and centralized configuration tools streamline system setup and modification.

- Ease of Maintenance and Troubleshooting: Localized faults are easier to diagnose and isolate.

- Operational Flexibility: Control strategies and interlock logic can be modified with relative ease.

- Improved Information Management: Process data is consolidated and presented in multiple, actionable formats.

6. Industrial Applications

DCS technology is foundational to continuous and batch process industries where high reliability and complex control are paramount. Typical applications include:

- Chemical, Petrochemical, and Oil Refineries

- Nuclear and Thermal Power Generation

- Environmental and Water/Wastewater Treatment Systems

- Pharmaceutical and Food Processing

- Metals, Mining, and Automotive Manufacturing

7. Frequently Asked Questions (FAQ)

- Q: What is a DCS?

- A: A Distributed Control System is a network of interconnected, localized controllers used for automated control of industrial processes, featuring centralized operator supervision.

- Q: What are the primary components of a DCS?

- A: Core components include Controllers, I/O Modules, Communication Networks, Human-Machine Interfaces (HMIs), an Engineering Workstation, and Field Devices.

- Q: What is the origin of DCS technology?

- A: The first commercially recognized DCS was introduced by Honeywell (the TDC 2000) in 1975, marking a shift from centralized mainframe control.