Current Transformer (CT) Fundamentals: Theory, Types, and Specifications

1. Theory of Operation

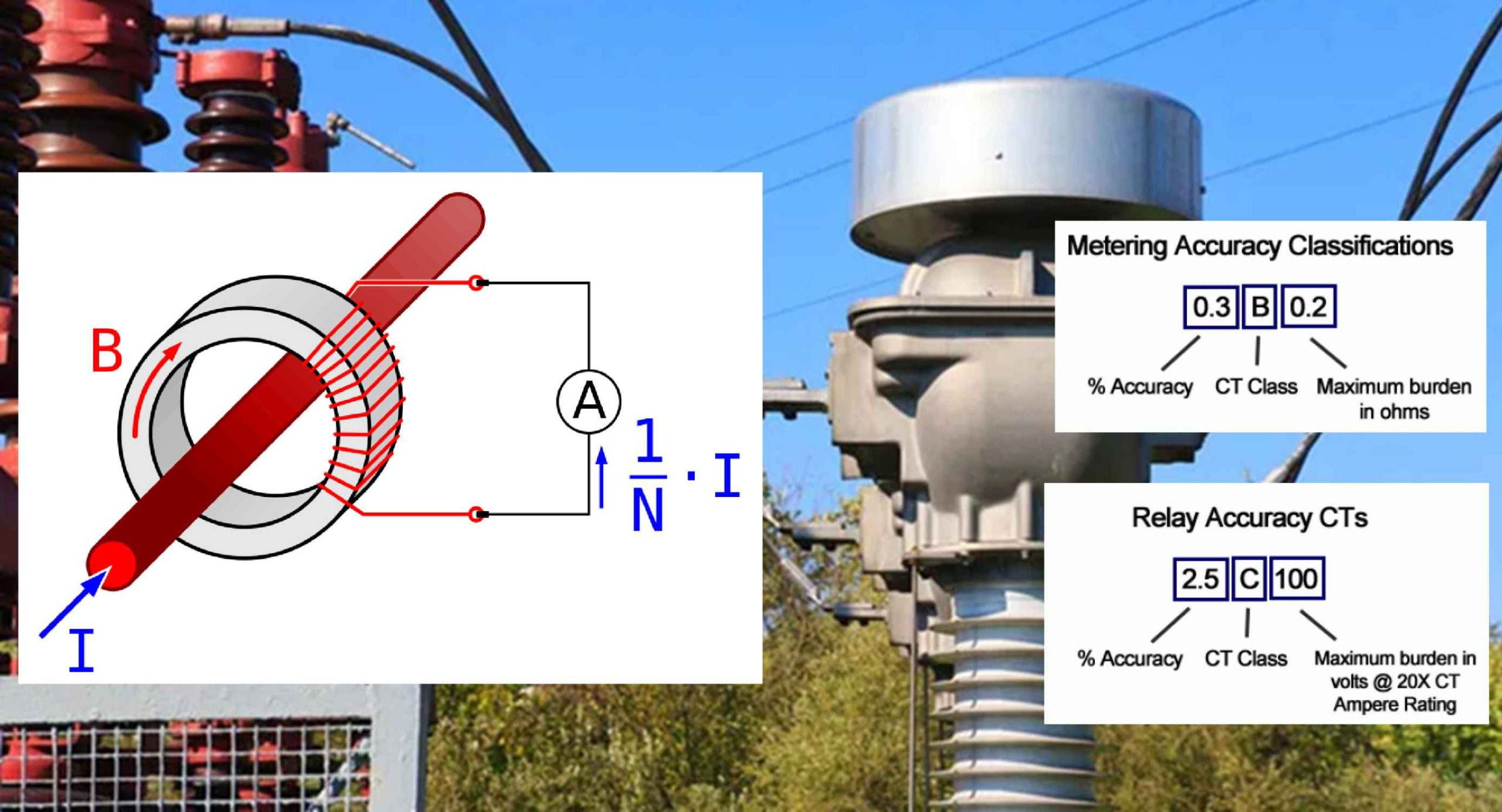

A Current Transformer (CT) is a type of instrument transformer designed to produce a manageable level of voltage and current, precisely proportional to the current flowing through its primary winding. This scaled output is essential for the safe and effective operation of measuring instruments, protective relays, and control devices.

In its fundamental form, a CT comprises a laminated steel core, a secondary winding wrapped around the core, and insulating material. When an alternating current (AC) passes through the primary conductor (which acts as the primary winding), it generates a magnetic field. This magnetic field magnetizes the iron core, inducing a voltage in the secondary coils. If the secondary circuit is closed, a current proportional to the CT ratio flows through it.

Critical Safety Warning: Open-Circuit CTs

DANGER: Current transformers must never be operated with an open secondary circuit. CTs are typically wired to a terminal block with shorting screws to ensure the secondary is always shorted when not connected to a load (burden). If the secondary circuit is opened while primary current is flowing, a dangerously high voltage can develop across the secondary terminals. This high voltage poses a severe risk of electric shock to personnel and can cause permanent damage to the CT’s insulation.

2. Current Transformer Types

Current transformers are broadly categorized into four main types based on their construction and application: window, bar, bushing, and wound. The primary winding can be formed by the main conductor passing through the core (window or bar type) or by a dedicated winding integrated with the secondary (wound type).

| CT Type | Primary Winding Configuration | Key Characteristics | Typical Application |

| Window | Primary conductor passes through the core aperture (no integrated primary winding). | Most common type. Available in solid-core (requires conductor disconnection for installation) or split-core (allows installation without disconnection). | Power monitoring, metering, and protective relaying. |

| Bar | A permanent bar is installed as the primary conductor, bolted directly to the current-carrying device. | Operates on the same principle as window CTs but features higher insulation levels. | Bolted connections to current-carrying devices. |

| Bushing | Specialized window CTs are designed to fit around a high-voltage bushing. | Nameplates are often located on the associated transformer or circuit-breaker control cabinet, as the CT itself is inaccessible. | High-voltage equipment bushings. |

| Wound | Features both a primary and secondary winding, similar to a standard transformer. | Rare, typically used at very low ratios and currents. Can have very high burdens. | Compensating for low currents, matching ratios in summing applications, or isolating circuits. |

A specialized application of the window CT is the Zero-Sequence CT. This type is used for ground fault sensing by surrounding all conductors (phases and neutral). Under normal conditions, the vector sum of these currents is zero. A ground fault creates an imbalance, which the CT detects and signals to a protective relay.

3. CT Specifications

3.1. CT Voltage Class

The CT Voltage Class specifies the maximum voltage the CT’s insulation can withstand if it comes into direct contact with a bare conductor. For instance, a 600V window CT can be installed around a 2400V cable, provided the CT is installed around the insulated portion of the cable, and the insulation is correctly rated.

3.2. CT Ratio

The CT Ratio is the ratio of the rated primary current input to the rated secondary current output at full load.

Example: A CT with a ratio of 300:5 is rated for 300 primary amperes (A) at full load and will produce 5 A of secondary current. If the primary current is 150 A, the secondary current will be 2.5 A.

Historically, the standard secondary current values were 5 A (common in the United States) or 1 A (adopted by other countries). With the advent of microprocessor-based meters and relays, the industry is increasingly adopting milliampere (mA) secondary outputs. Devices with mA output are often referred to as “current sensors” rather than traditional current transformers.

Note: The CT ratio expresses the current rating of the CT, not merely the ratio of the primary to secondary currents. A 100/5 CT is not functionally equivalent to a 20/1 or a 10/0.5 CT.

3.3. CT Polarity

CT Polarity is determined by the direction of the secondary winding around the core and the way the secondary leads are brought out. All modern current transformers are of subtractive polarity.

Proper installation is guided by the following standard designations:

- H1: Primary current terminal, facing the source (line side).

- H2: Primary current terminal, facing the load.

- X1: Secondary current terminal (the polarity mark).

- X2: Secondary current terminal.

On subtractive polarity transformers, the H1 primary lead and the X1 secondary lead are on the same side of the transformer. Polarity may also be indicated by an arrow, which should point in the direction of current flow (from source to load). Correct polarity is crucial for accurate power metering and the proper functioning of protective relays.

Field Polarity Test (9V Battery Method)

To verify the polarity of a CT in the field, the following procedure can be used:

- Safety: Disconnect all power prior to testing.

- Set up: Connect an analog voltmeter to the CT secondary terminals. Connect the positive meter lead to the X1 terminal and the negative meter lead to the X2 terminal.

- Test: Run a piece of wire through the CT window (the primary conductor). Momentarily touch the positive end of a 9-volt battery to the H1 side of the wire and the negative end to the H2 side.

- Result: If the polarity is correct, the momentary contact will cause a small, positive deflection on the analog meter. A negative deflection indicates reversed polarity, requiring the X1 and X2 connections to be switched.

4. CT Accuracy Class

Since no transformer is ideal, small energy losses (e.g., eddy currents, heat) cause the secondary current to deviate slightly from the perfectly calculated value. The Accuracy Class of a CT quantifies the permissible deviation (error) between the actual secondary current magnitude and the calculated value based on the CT ratio.

CTs are divided into two primary categories based on their accuracy class:

- Metering Accuracy CTs: Designed to be highly accurate from very low current up to the maximum current rating. They are typically used for revenue metering and billing purposes.

- Protection (Relay) Accuracy CTs: Designed to maintain a reasonable degree of accuracy over a much wider range of current, including high fault currents. They are used to supply current to protective relays.

The CT accuracy class is defined by a number-letter-number combination as set forth in standards such as ANSI C57.13. This combination is broken into three parts:

4.1. Rated Ratio Accuracy Rating

This is the accuracy rating expressed as a percentage. For example, a CT with an accuracy class of 0.3B0.1 is certified to be accurate to within 0.3 percent of its rated ratio value when the primary current is 100 percent of the rated ratio.

4.2. Class Rating

The letter designates the application and manufacturing characteristics of the CT:

| Class Letter | Meaning | Characteristics | Typical CT Type |

| C | Calculated | Indicates low leakage flux, meaning accuracy can be calculated prior to manufacturing. | |

| T | Tested | Indicates significant leakage flux, requiring the accuracy to be determined by factory testing. | |

| H | High-Current Range | Accuracy is applicable across the entire range of secondary currents from five to 20 times the nominal CT rating. | Typically, Wound CTs. |

| L | Low-Current Range | Accuracy applies only at the maximum rated secondary burden at 20 times rated current. Ratio accuracy can degrade at lower currents. | Typically, Window, Bushing, or Bar-type CTs. |

4.3. Maximum Burden

The third part of the accuracy class specifies the maximum permissible load (or burden) that can be connected to the secondary circuit while maintaining the stated accuracy. If this limit is exceeded, the CT’s accuracy cannot be guaranteed.

Metering Class Burden

For Metering Class CTs, the burden is expressed as ohms impedance (B-rating).

Example: A 0.3B0.1 rated CT is accurate to 0.3 percent if the connected secondary burden impedance does not exceed 0.1 ohms.

Relay Class Burden

For Relay Class CTs, the burden is expressed as volt-amperes (VA) or as a C-rating (e.g., C100). The C-rating represents the maximum secondary voltage allowable if 20 times the CT rating (e.g., 100 A for a 5 A secondary CT) were to flow through the secondary circuit.

Example: A 2.5C100 protection CT is accurate within 2.5 percent if the secondary burden is less than 1 ohm (calculated as 100 volts / 100 amperes).

Calculating Total CT Burden

To ensure the CT operates within its specified accuracy, the total connected burden must be calculated and verified against the CT’s maximum burden rating:

- Device Burden: Determine the burden (in VA or ohms) of all devices connected to the CT secondary (e.g., relays, meters).

- Wire Burden: Calculate the secondary wire impedance based on its length and gauge.

- Verification: Sum the device and wire burdens. This total must not exceed the maximum burden specified on the CT’s nameplate.