Instrument Transformers: A Comprehensive Guide to Types, Specifications, and Field Testing

Instrument transformers (ITs) are fundamental components in modern electrical power systems, serving as the critical interface between high-voltage (HV) and high-current primary circuits and low-voltage measuring, control, and protective devices. Their primary function is to step down the system voltage and current to safe, standardized, and manageable levels, typically 120 V or 5 A, respectively. This isolation is essential for personnel safety and the accurate operation of sensitive secondary equipment.

This guide expands upon the basic concepts of ITs, detailing their various types, key technical specifications, and the comprehensive testing procedures required to ensure their long-term reliability and accuracy in accordance with industry standards such as those published by the Institute of Electrical and Electronics Engineers (IEEE) and the National Electrical Testing Association (NETA).

Section 1: Instrument Transformer Types and Applications

Instrument transformers are broadly classified into Current Transformers (CTs) and Voltage Transformers (VTs), with specialized variants designed for specific system requirements.

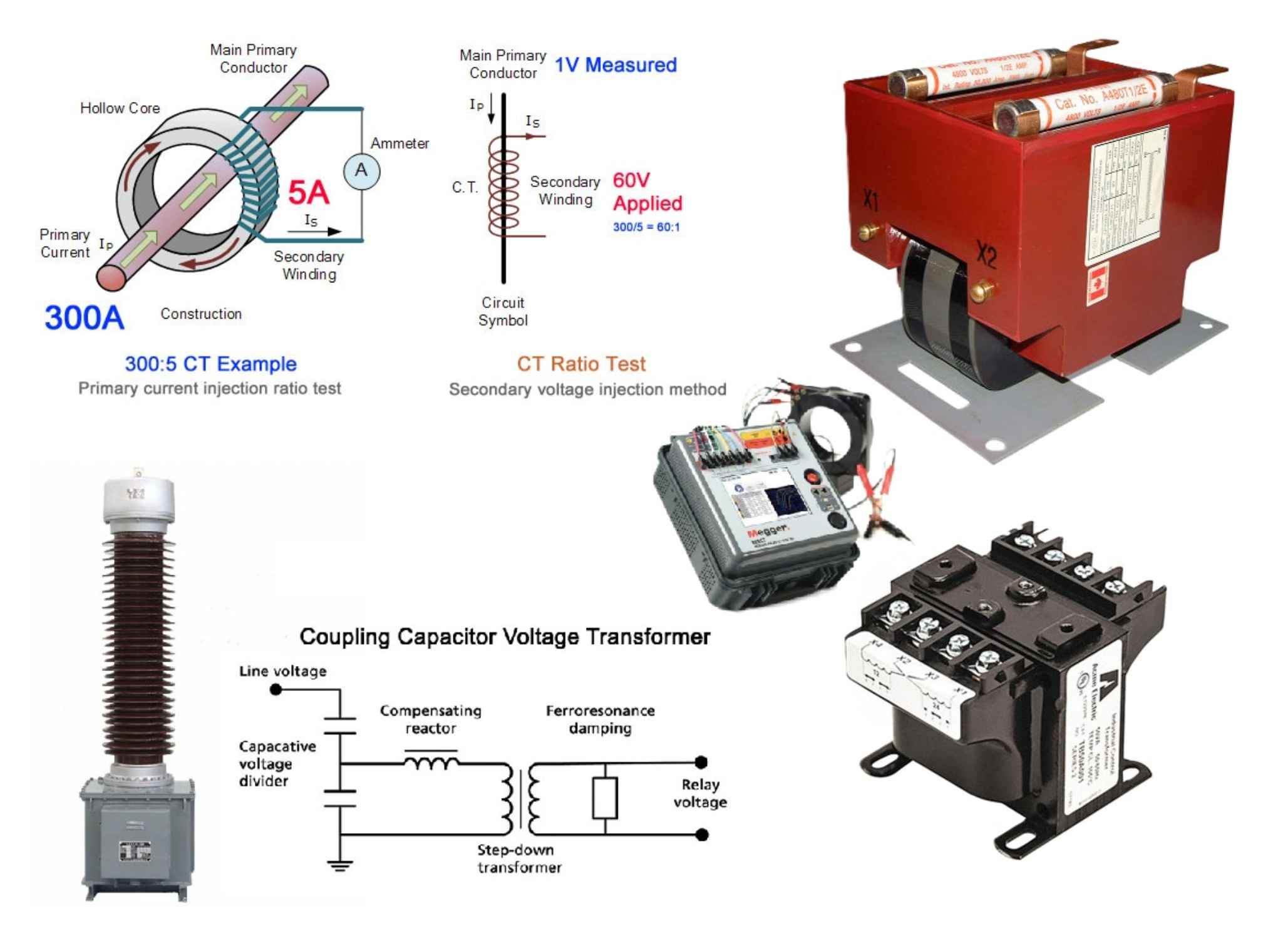

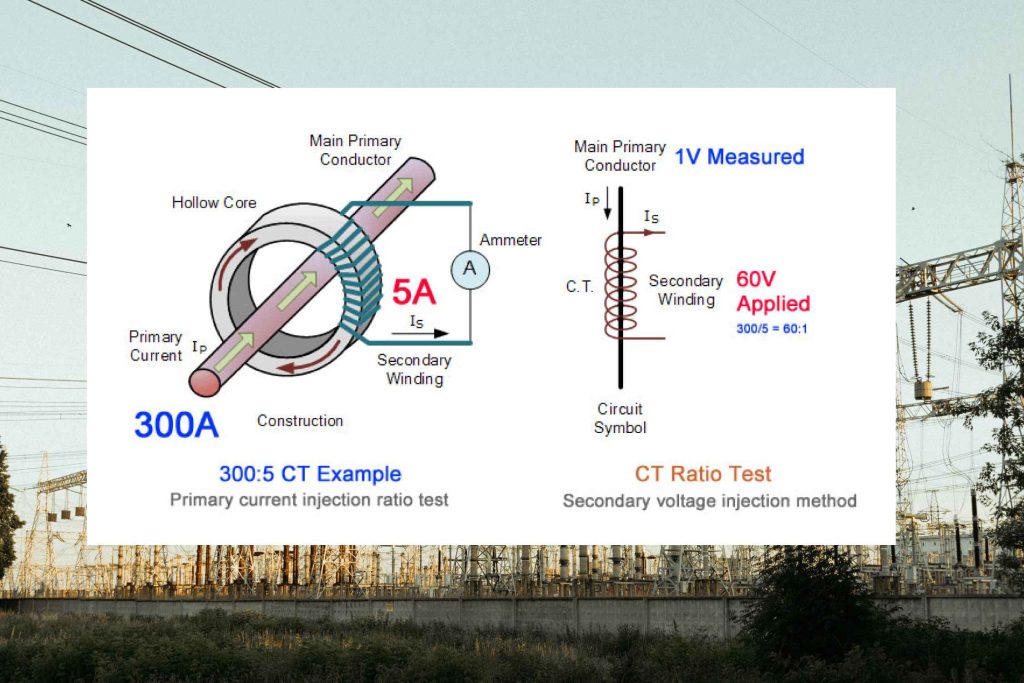

1.1 Current Transformers (CTs)

A Current Transformer (CT) is designed to produce a proportional, reduced current in its secondary winding, which is accurately representative of the current flowing in its primary circuit.

| CT Type | Description | Primary Application |

| Wound CT | Features a primary winding physically connected in series with the main conductor. Provides the highest accuracy and is often used for metering. | Metering, high-accuracy applications. |

| Window CT | Has no primary winding; the main power conductor passes through a central opening (window) to act as a single-turn primary. | Protection, large bus or cable installations. |

| Bushing CT | A specialized window CT is installed around the bushing of a circuit breaker or power transformer. It is cost-effective but generally less accurate. | Protection, fault detection. |

| Bar-Type CT | Similar to a wound CT, but the primary winding is a solid bar of metal passing through the core. Offers better mechanical strength than wound types. | Switchgear, medium-voltage applications. |

Key CT Specifications: Metering vs. Protection

CTs are categorized based on their intended use, which dictates their accuracy requirements under different operating conditions :

- Metering CTs (T-Class): Must maintain high accuracy (e.g., 0.3% or 0.6%) across the normal operating range (5% to 120% of rated current). Accuracy is not guaranteed under fault conditions.

- Protection CTs (C-Class): Must maintain accuracy up to a high multiple of the rated current (e.g., 20 times), ensuring the protective relay receives an accurate signal during a fault. Their performance is defined by the knee point on the excitation curve, which marks the onset of magnetic saturation.

1.2 Voltage Transformers (VTs) and Potential Transformers (PTs)

Voltage Transformers (VTs), often referred to as Potential Transformers (PTs), are parallel-connected devices that step down the primary voltage to a safe secondary level, typically 120 V. They are essentially high-accuracy power transformers with low power ratings.

- Inductive VTs/PTs: These are the most common type, operating on the principle of electromagnetic induction. They are used in medium- and high-voltage systems for metering and protection.

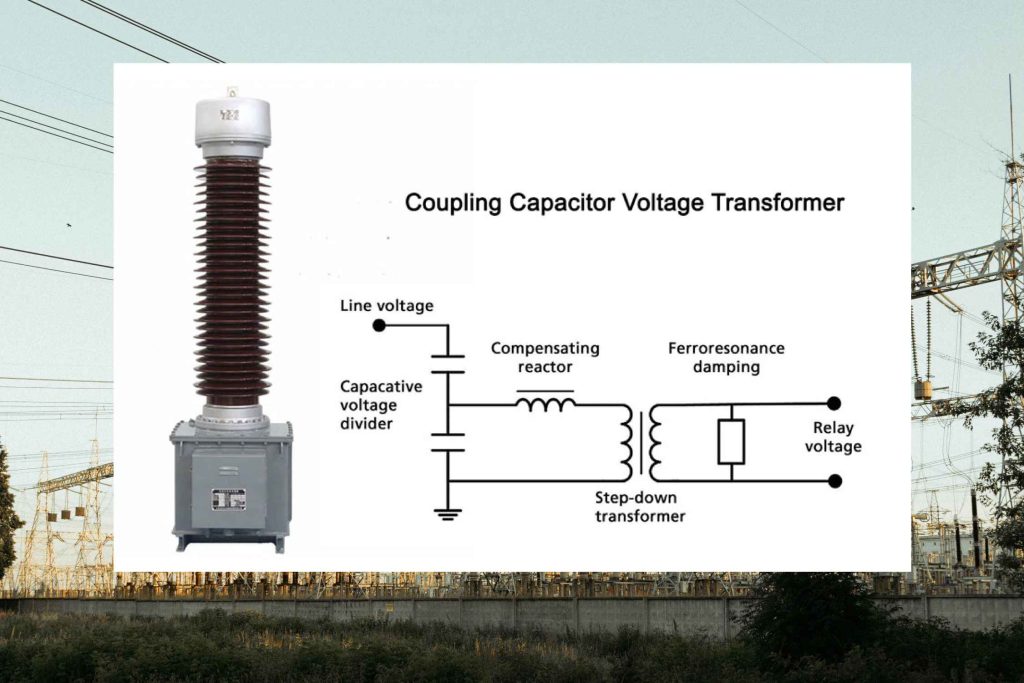

1.3 Capacitor Coupled Voltage Transformers (CCVTs)

The Capacitor Coupled Voltage Transformer (CCVT) is a specialized VT used almost exclusively in extra-high voltage (EHV) systems (typically 69 kV and above). The CCVT design utilizes a capacitive voltage divider to reduce the high primary voltage to an intermediate level (e.g., 5-20 kV).

This intermediate voltage is then further stepped down by a small Electromagnetic Unit (EMU) to the standard secondary voltage (e.g., 120 V). CCVTs are more economical than inductive VTs at EHV levels and can also serve as coupling capacitors for Power Line Carrier Communication (PLCC).

1.4 Control Power Transformers (CPTs)

While not strictly an instrument transformer for measurement, the Control Power Transformer (CPT) is a vital auxiliary transformer. Its function is to provide a reliable, isolated source of low-voltage power (e.g., 120 V AC or 24 V DC) to control circuits, motor starters, switchgear controls, and protective relays. CPTs ensure that the control system remains operational and isolated from the main power system’s higher voltages.

Section 2: Essential Field Testing Procedures

Periodic testing of instrument transformers is mandated by industry standards (e.g., NETA ATS, IEEE C57.13) to detect degradation, ensure continued accuracy, and verify the integrity of the insulation system. Neglected IT can compromise system protection, leading to equipment damage or catastrophic failure.

2.1 Current Transformer (CT) Testing

The following electrical tests are critical for assessing CT performance in the field:

| Test Name | Purpose | Key Measurement/Result | Standard Reference |

| Ratio Verification | Confirms the nameplate turns ratio (e.g., 400:5) and detects shorted turns or incorrect connections. | Measured ratio must be within the specified accuracy class tolerance (e.g., 0.3%). | ANSI/IEEE C57.13.1 |

| Polarity Test | Verifies the correct relationship between the primary (H1, H2) and secondary (X1, X2) terminals, essential for proper relay operation. | Correct polarity is confirmed by a momentary deflection (kick) of a voltmeter in a specific direction (e.g., DC Kick Test). | ANSI/IEEE C57.13.1 |

| Excitation (Saturation) Test | Determines the knee point voltage ($V_k$) and excitation current, which are vital for protection CTs (C-Class). | The knee point voltage must meet or exceed the minimum value specified by the manufacturer or standard. | ANSI/IEEE C57.13.1 |

| Burden Test | Measures the actual impedance (load) of the secondary circuit (wiring, meters, relays) connected to the CT. | The measured burden must be less than the CT’s rated burden to prevent excessive ratio error. | ANSI/IEEE C57.13.1 |

| Insulation Resistance | Checks the integrity of the insulation between windings and to ground. | Measured resistance must meet minimum values (e.g., 100 MΩ) as per NETA/manufacturer guidelines. | NETA ATS |

2.2 Voltage Transformer (VT/PT) and CCVT Testing

Testing procedures for VTs and CCVTs focus on ratio accuracy, insulation integrity, and, for CCVTs, the condition of the capacitive elements.

| The measured ratio must be within the specified tolerance of the accuracy class. | Purpose | Key Measurement/Result | Standard Reference |

| Turns-Ratio Test | Verifies the transformation ratio of the inductive element against the nameplate. | Measured ratio must be within the specified accuracy class tolerance. | NETA ATS |

| Polarity Test | Confirms the correct H1-X1 relationship, similar to CTs. | Correct polarity is confirmed. | NETA ATS |

| Insulation Resistance | Checks the integrity of the insulation between windings and to ground. | Measured resistance must meet minimum values. | NETA ATS |

| Power Factor (Tan Delta) Test | Measures the dielectric loss in the insulation system, a sensitive indicator of moisture, contamination, or insulation degradation. | Power factor (or dissipation factor) must be below the maximum acceptable limit (e.g., 0.5% to 1.0%). This is especially critical for CCVTs. | ANSI/IEEE C57.13 |

| Capacitance Measurement | (CCVTs only) Measures the capacitance of the high-voltage capacitor stack to detect internal shorts or open circuits. | Measured capacitance must be within a few percent of the nameplate value. | ANSI/IEEE C93.1 |

Conclusion

Instrument transformers are the unsung heroes of power system reliability, providing the essential data for both accurate revenue metering and rapid fault protection. Understanding the distinct characteristics of CTs, VTs, CCVTs, and CPTs, and adhering to rigorous, periodic testing protocols, are paramount. These tests—from ratio and polarity checks to advanced saturation and power factor analysis—ensure that the entire power system operates safely, efficiently, and in compliance with international standards.

References

- Electrical Engineering Portal. Inspection and Test procedures for Instrument Transformers.

- IEEE. IEEE Standard Requirements for Instrument Transformers.

- [3] Ergon Energy. Voltage Transformer Testing.

- [4] NETA. Acceptance Testing Specifications.