Analysis and Compliance of Earth Fault Loop Impedance for Protective Device Operation

Abstract

This article provides a theoretical and procedural analysis of Earth Fault Loop Impedance (EFLI), a critical parameter in electrical safety engineering. The primary objective is to elucidate the relationship between EFLI, automatic disconnection times of protective devices, and the subsequent sizing of protective earthing conductors, ensuring full compliance with the safety mandates of AS/NZS 3000:2018 (Wiring Rules). The discussion covers theoretical foundations, calculation methods for both actual (Zs) and maximum permissible (Zmax) impedance, and the practical application of these principles in design and verification processes, with reference to computational tools such as Cable Pro Web.

1.0 Introduction

The safe operation of low-voltage electrical installations fundamentally relies on the principle of automatic disconnection of supply in the event of an earth fault. This safety mechanism, designed to protect against electric shock from indirect contact, is governed by the impedance of the earth fault loop path. This paper examines the theoretical framework of Earth Fault Loop Impedance, details the compliance requirements stipulated by AS/NZS 3000, and outlines the calculation procedures necessary to verify that protective devices will operate within prescribed time limits. Mastery of these concepts is essential for engineers and designers responsible for the safety, design, and testing of electrical installations in Australia and New Zealand.

2. Theoretical Framework of the Earth Fault Loop

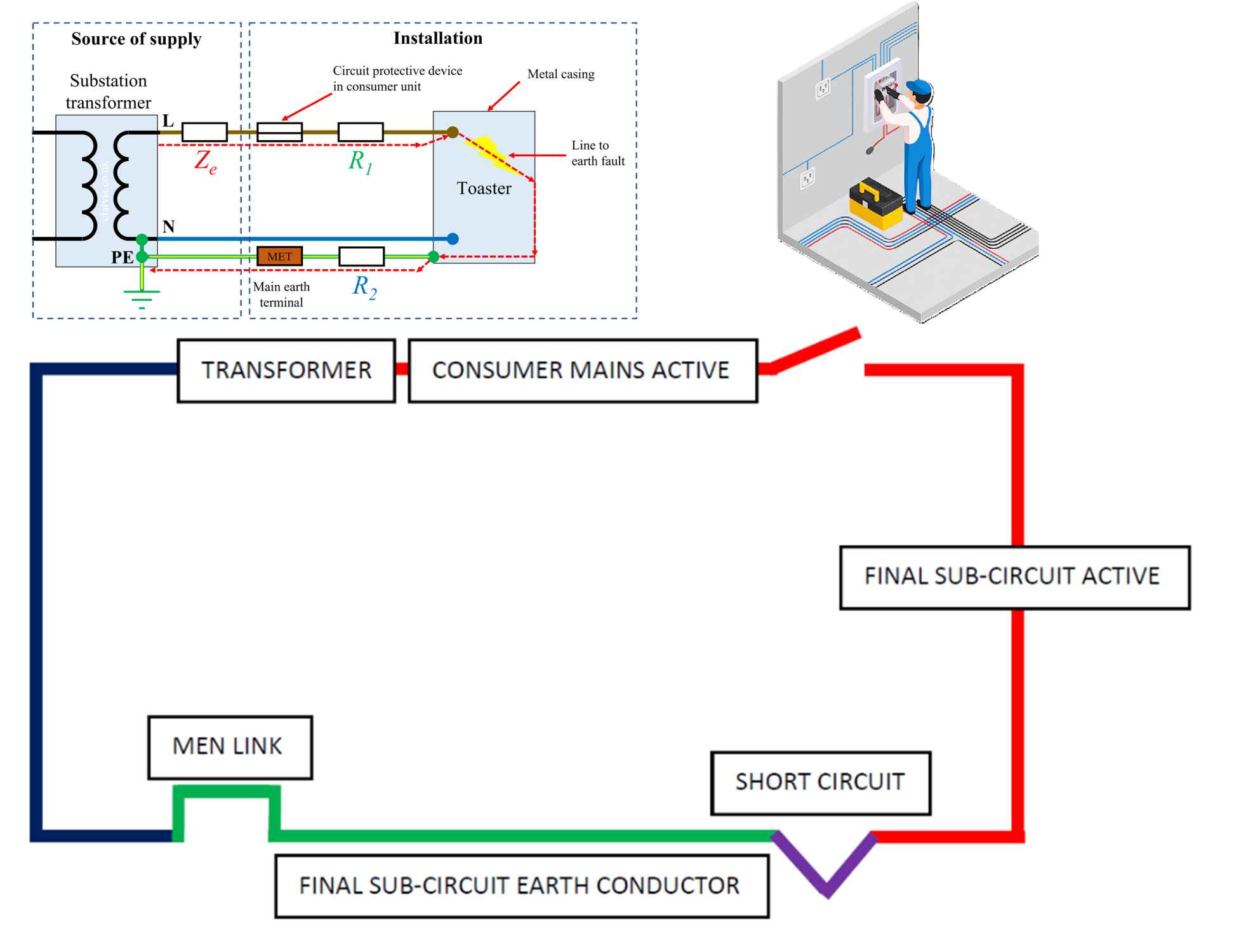

In a Multiple Earthed Neutral (MEN) system, the earth fault loop for an active-to-earth short circuit comprises a series of components: the protective earthing (PE) conductor back to the main earth terminal, the connection to the neutral via the MEN link, the neutral conductor to the transformer star point, the transformer winding, and the active conductor up to the point of fault.

The total loop impedance (Zs) is the phasor sum of the impedances of all elements in this path. Analytically, it is often segmented into two parts for calculation:

- External Impedance (Zext): The impedance upstream of the reference point (typically the origin of the installation), including the supply transformer and service cables.

- Internal Impedance (Zint): The impedance downstream from the reference point, encompassing the installation’s active and protective earth conductors to the farthest point of the circuit.

A simplified schematic of this loop is presented in Figure 2. The magnitude of the prospective earth fault current (Ipf) is limited by Zs (Ipf ≈ Uo / Zs, where Uo is the nominal phase-to-earth voltage).

AS/NZS 3000, referenced in legislation across Australia and New Zealand, mandates that every circuit be designed to ensure automatic disconnection occurs within specified times upon a fault with negligible impedance between an active conductor and an earthed part. Compliance hinges on providing the actual earth fault loop impedance (Zs) is sufficiently low to permit a fault current magnitude (Ia) that will guarantee the operation of the associated protective device—whether a circuit-breaker or fuse—within the time stipulated by the Standard. Therefore, the core design and verification task involves calculating or measuring the actual impedance (Zs) and comparing it against the maximum permissible impedance (Zmax) for the protective device in question.

4. Calculation of Earth Fault Loop Impedance

4.1 Actual Impedance (Zs)

The total earth fault loop impedance is approximately Zs = Zext + Zint.

- Zint is calculated from the impedance of the active and earth conductors for the circuit length, utilizing resistance and reactance data from AS/NZS 3008.1.

- Zext is often derived using the guideline in AS/NZS 3000, which assumes that at least 80% of Uo is available at the origin of the installation under fault conditions.

4.2 Maximum Permissible Impedance (Zmax)

Zmax is the highest impedance at which the protective device will still operate within the required time. It is derived from the formula:

Zmax = Uo / Ia

Where Ia is the current causing automatic operation of the protective device within the specified time.

- For circuit-breakers, Ia is the mean tripping current (e.g., 4–5 x In for Type B, 7.5–10 x In for Type C, 10–20 x In for Type D).

- For fuses, Ia values are obtained from standards such as AS 60269.1.

The safety condition is satisfied when Zs < Zmax.

5. Sizing of Protective Earthing Conductors

The cross-sectional area of the protective earth (PE) conductor must satisfy three key criteria:

- Earth Fault Loop Impedance: It must contribute to an overall Zs that is less than Zmax.

- Thermal Withstand (Adiabatic): It must have sufficient cross-sectional area to carry the prospective earth fault current for the duration of the protective device’s clearing time without sustaining damage, as per the adiabatic equation in AS/NZS 3008.1.

- Mechanical Strength: It must meet the Standard’s minimum sizing requirements.

AS/NZS 3000 provides two primary methods for selection:

(a) Tabular Method: Using Table 5.1, which specifies a conservative earth conductor size relative to the associated active conductor(s).

(b) Calculation Method: A more precise calculation based on the known characteristics of the protective device, which typically results in a smaller, optimised conductor size while ensuring compliance with both the impedance and adiabatic requirements.

6. Computational Application

Software tools such as Cable Pro Web automate these complex calculations, ensuring accuracy and compliance. Such tools can implement both the conservative tabular method and the precise calculation method, automatically determining Zs, verifying it against Zmax, and selecting an appropriate earth conductor size that also satisfies the adiabatic thermal constraint.

7. Conclusion

The rigorous analysis and application of earth fault loop impedance principles are indispensable for achieving the fundamental safety objective of automatic disconnection. By correctly calculating Zs and Zmax, and subsequently sizing the protective earthing conductor to meet both impedance and thermal requirements, designers can ensure electrical installations fully comply with AS/NZS 3000, thereby safeguarding persons and property from the dangers of earth faults.