Routine Inspections and Checks for Liquid-Filled Transformers

Transformers are essential components in electrical power distribution systems, renowned for their reliability. However, a transformer failure is typically a severe event, often necessitating extensive repairs and prolonged downtime. Consequently, implementing regular preventive maintenance procedures is the most effective strategy for ensuring continued high reliability and operational longevity.

The extent and frequency of maintenance should be determined not only by the transformer’s size or voltage level but also by its criticality within the overall system. The following sections detail three routine inspections that are fundamental to a comprehensive maintenance program.

Safety Precaution

It is paramount that a liquid-filled transformer be regarded as energized until the tank ground connection has been thoroughly inspected and confirmed to be adequate. This is a mandatory safety requirement as stipulated by the Occupational Safety and Health Administration (OSHA) standard 29 CFR 1910.269(l)(11).

1. Liquid Level Monitoring

The core and coils of liquid-filled transformers are submerged in an insulating fluid, which serves two critical functions:

- Insulation: It forms a vital part of the transformer’s dielectric medium.

- Cooling: It transfers heat away from the windings, allowing the heat to be dissipated by the cooling fins, tank surface, or radiator.

The liquid level gauge indicates the volume of insulating fluid within the tank. Regular checks at this level are essential, particularly after a prolonged period of low load at low ambient temperatures, when the level is expected to be at its lowest.

Inspection Procedures

- With a Gauge: The liquid level indicator is typically calibrated to a reference temperature, such as 25°C, under normal operating conditions. It is crucial to add fluid before the level drops below the sight glass or the lowest reading on the indicator.

- Without a Gauge: If a transformer lacks a liquid-level indicator, the level can be checked by removing the inspection plate on the top of the transformer or by removing the entire top if no plate is available. The transformer must be de-energized prior to performing either of these procedures.

Record Keeping and Fluid Testing

For effective condition monitoring, liquid level readings taken at the end of a low-load period should be correlated with current, voltage, and temperature measurements taken at peak load. These readings are best achieved using external metering while strictly observing all safety precautions. Permanent records of these readings must be maintained for comparison against previous data under similar operating conditions. Furthermore, periodic testing of the insulating fluid is highly recommended, with samples typically drawn from the tank drain valve.

2. Temperature Readings

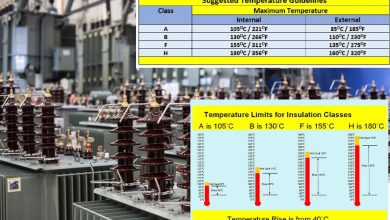

Continued operation of a transformer at an over-temperature condition will significantly accelerate deterioration of the insulating liquid and the solid insulation, thereby reducing the unit’s life expectancy and greatly increasing the risk of catastrophic failure. Transformers are designed to carry their nameplate load (in kVA) with a specified heat rise at a standard ambient temperature. For instance, a liquid-filled transformer might be rated to deliver its full capacity with a 65°C (149°F) temperature rise above a 30°C (86°F) 24-hour average ambient temperature. The exact temperature rise values are listed on the transformer’s nameplate.

Monitoring and Action

If the transformer is equipped with temperature gauges, readings should be taken and recorded regularly. If the gauge includes a maximum-temperature indicator, both the current and maximum readings should be recorded, and the maximum indicator should then be reset.

Excessive temperatures are a clear indication of an overload or a potential issue with the cooling system, requiring immediate investigation. To ensure constant protection against overheating, special alarm contacts can be installed on the temperature gauge to provide automated alerts.

3. Pressure/Vacuum Gauge Observation

The pressure/vacuum gauge, commonly found on sealed-type transformers, is a critical indicator of the integrity of the sealed tank construction. Whenever feasible, these gauges should be added to sealed transformers that have provisions for their installation.

Interpreting Readings

Readings from this gauge must be compared against the manufacturer’s recommendations for the normal operating range.

- High Pressure: Indicates an overload or internal trouble within the tank and warrants immediate investigation.

- Sustained Zero Pressure: Suggests a leak in the sealed system or a defective gauge, both of which compromise the transformer’s internal environment and require prompt attention.