The Ten Principal Causes of Transformer Winding Failure

Power transformers are indispensable assets in electrical power systems, serving as critical links for efficient power transmission and distribution. Given their central role, a fault within a transformer is often a catastrophic event, leading to extensive downtime, significant financial loss (potentially exceeding $1,000,000 for a single substation unit), and widespread power interruptions. The windings are the core functional component, and their integrity is paramount. Failure of the winding insulation or conductor material is the most common precursor to transformer failure. The following report details the ten principal causes of transformer winding failure, categorized by the primary stressor: electrical, thermal, mechanical, and environmental.

Principal Causes of Winding Failure

1. Turn-to-Turn Faults

These are among the most frequent and destructive internal faults. They occur when the insulation between adjacent turns of a winding breaks down. This breakdown is primarily driven by thermal stresses from inadequate heat dissipation (overloading) and dielectric stresses from poor power quality, such as voltage spikes and harmonics. The resulting short-circuit current generates intense localized heat, leading to rapid insulation degradation, potential core deformation, and, in severe cases, explosion.

2. Surges (Overvoltage)

Transient overvoltages, typically caused by lightning strikes or switching operations within the power grid, can be transferred through the transformer’s magnetic coupling. These high-frequency, high-magnitude voltage impulses subject the winding insulation to extreme dielectric stress, often leading to immediate or latent turn-to-turn insulation failure. The installation of surge arresters is a standard mitigation technique to divert these currents to ground, protecting the transformer.

3. Moisture Ingress

The presence of moisture is highly detrimental to the insulation system of both liquid-filled and dry-type transformers. In liquid-filled units, moisture reduces the dielectric strength (breakdown voltage) of the insulating oil and accelerates the irreversible degradation of the paper insulation. Ingress can occur through improperly sealed tanks, poor fluid sampling techniques, or inadequate maintenance of the silica gel breather. Dry-type transformers are also vulnerable, particularly in high-humidity environments, as their large ventilation ports allow for moisture accumulation.

4. External Faults (Through-Faults)

These are system-level events that originate outside the transformer but impose severe stresses upon it. Examples include short circuits on the low-voltage side, line-to-ground faults, or external physical damage (e.g., downed trees, animal contact). While not preventable by internal transformer maintenance, these faults cause high through-fault currents and associated mechanical forces on the windings, which can lead to winding displacement or insulation damage.

5. Overheating (Thermal Stress)

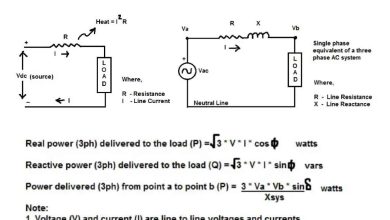

Sustained high operating temperatures are a primary accelerator of insulation aging. Overheating can result from persistent overloading, restricted heat transfer due to a dirty enclosure or blocked airflow, or the presence of harmonics. Harmonics, particularly the third and fifth order, are often introduced by non-linear electronic loads and can cause excessive current flow in the neutral termination, leading to localized thermal hot spots that severely reduce the transformer’s service life.

6. Open Winding

An open winding condition is a discontinuity in the winding circuit, often resulting from a broken conductor, a loose connection, or a blown fuse in the primary circuit. This condition is particularly prevalent in remote or rural areas. It can lead to a single-phasing condition, where the resulting voltage and current imbalances place abnormal stress on the remaining phases, potentially causing secondary winding failure or damage to connected loads.

7. Deterioration (Aging and Neglect)

This cause encompasses the general degradation of the insulation system over time, often exacerbated by a reactive maintenance approach. The natural aging process, combined with cumulative thermal and electrical stresses, leads to a progressive loss of mechanical and dielectric integrity. Poor electrical maintenance, including a lack of regular visual inspections and periodic insulating fluid analysis, is the leading cause of premature equipment failure.

8. Core Faults

Transformer cores are constructed from stacked, thin iron laminations separated by a non-conducting layer of insulation. Over time, the adhesive or insulation separating these laminations can degrade. This degradation allows for an increase in eddy currents, which generate excess heat. This heat is then transferred to the windings, accelerating insulation aging and potentially leading to winding failure. The audible humming of a transformer often increases in volume as core insulation degradation progresses.

9. Phase-to-Phase Faults

These are unintended short circuits that occur between two or more phases within the transformer. They can be triggered by a variety of internal issues, including severe overheating, contamination of the insulating oil, or a localized failure of the main insulation system. Failure can also occur between the high-voltage (HV) and low-voltage (LV) windings where they are wrapped around a common phase, resulting in a major fault condition.

10. Mechanical Failures

Mechanical failures refer to the malfunction of auxiliary equipment critical to the transformer’s operation or protection. This includes the failure of the cooling system (e.g., pumps, fans, radiators), which leads to elevated winding temperatures and thermal failure, or the failure of an upstream circuit breaker to clear a fault. The inability of protective devices to isolate a fault quickly subjects the transformer to prolonged, damaging stresses.

Summary of Transformer Winding Failure Causes

The following table summarizes the ten principal causes of winding failure, highlighting the primary stressor and the resulting failure mechanism.

| No. | Cause | Primary Stressor | Typical Failure Mechanism |

| 1 | Turn-to-Turn Faults | Thermal / Dielectric | Localized insulation breakdown, short-circuit current, explosion risk |

| 2 | Surges | Dielectric (Transient) | High-voltage impulse, immediate or latent insulation puncture |

| 3 | Moisture Ingress | Environmental / Chemical | Reduced oil dielectric strength, accelerated paper insulation degradation |

| 4 | External Faults | Mechanical (Dynamic) | Increased eddy currents, excess heat generation, and winding insulation stress |

| 5 | Overheating | Thermal (Sustained) | Accelerated insulation aging, reduced service life, thermal runaway |

| 6 | Open Winding | Electrical (Systemic) | Single-phasing condition, voltage/current imbalance, secondary failure |

| 7 | Deterioration | Time / Maintenance | Progressive loss of dielectric and mechanical integrity due to aging and neglect |

| 8 | Core Faults | Thermal / Electrical | Increased eddy currents, excess heat generation, winding insulation stress |

| 9 | Phase-to-Phase Faults | Dielectric / Thermal | Major insulation failure between phases, severe short-circuit |

| 10 | Mechanical Failures | Auxiliary System | Loss of cooling, prolonged fault exposure due to protection failure |

Conclusion

The reliability of a power transformer is directly proportional to the integrity of its winding insulation system. The ten causes detailed above demonstrate that winding failure is a complex phenomenon resulting from a combination of electrical, thermal, mechanical, and environmental stressors. The most effective strategy for mitigating these risks is a robust, proactive maintenance program. This includes continuous monitoring for thermal anomalies, periodic analysis of insulating fluid (oil), and regular electrical testing to detect early signs of insulation deterioration, thereby ensuring the continued high reliability and extended service life of these critical assets.