Insulating Fluids in Electrical Equipment: Properties, Types, and Testing

Insulating fluids, often referred to as dielectric fluids, are essential components in liquid-filled electrical apparatus such as transformers, regulators, and circuit breakers. These fluids serve a dual purpose: providing electrical insulation and facilitating heat transfer (cooling). Regular analysis of the insulating fluid is critical, as it offers valuable insights into the equipment’s condition and helps identify potential failures before they occur.

Key Properties of Insulating Fluids

A set of physical and electrical properties determines the performance and suitability of a dielectric fluid. Understanding these characteristics is vital for equipment maintenance and fluid selection.

| Property | Definition | Significance for Performance |

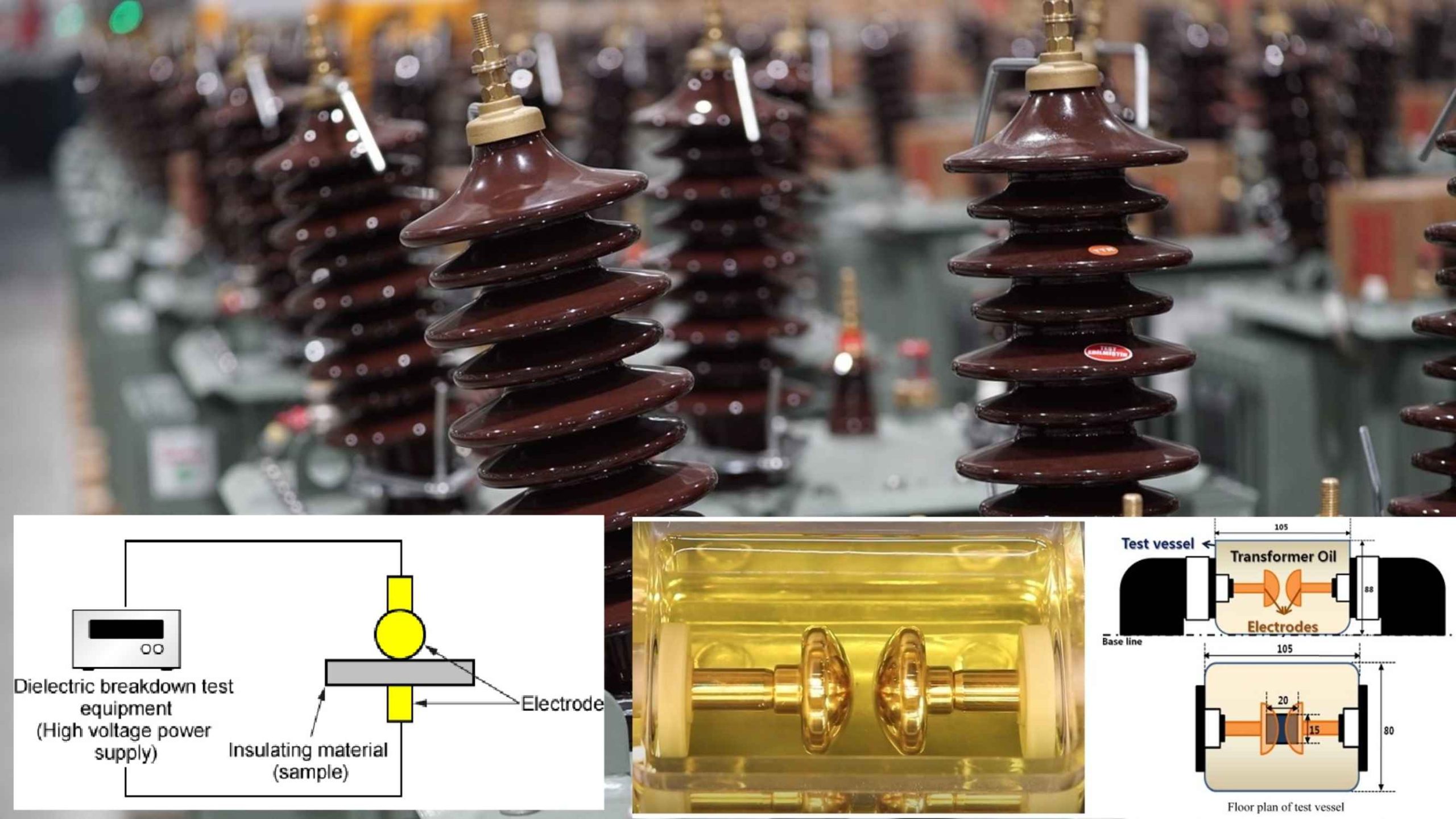

| Dielectric Breakdown Voltage | The maximum voltage the fluid can withstand before electrical breakdown occurs. | A measure of the fluid’s insulating strength. |

| Power Factor (Dissipation Factor) | The ratio of energy dissipated as heat to the total energy transmitted through the fluid. | Indicates the fluid’s electrical efficiency. A lower power factor suggests better insulation and less contamination/deterioration. |

| Viscosity | The fluid’s internal resistance to flow, or “thickness.” | Affects heat transfer. A lower viscosity allows for better circulation and more efficient heat dissipation. |

| Specific Gravity (SG) | The ratio of the fluid’s density to the density of water (SG = 1.0). | Determines the migration of free water within the apparatus. Since dielectric strength is inversely related to water content, the fluid’s SG is crucial for managing moisture. |

| Interfacial Tension (IFT) | The force of attraction between the molecules at the interface of the fluid (e.g., oil) and water. | A decreasing IFT value is a strong indicator of soluble contaminants and oxidation products within the fluid. |

| Pour Point | The lowest temperature at which the insulating fluid will flow. | Ensures the fluid can circulate and perform its cooling and insulating functions in cold climates. |

| Biodegradability | The ability of the fluid to decay through the action of living organisms. | A direct measure of the fluid’s environmental impact in the event of a spill or uncontained release. |

Major Types of Insulating Fluids

The modern market uses several common types of insulating liquids, each with unique properties that dictate its specific applications. The four primary types are mineral oil, silicone, hydrocarbon, and natural esters.

1. Mineral Oil

Conventional mineral oil is the oldest and most widely used dielectric fluid. It is a preferred option for outdoor transformers due to its established record of high dielectric strength and thermal performance. The primary drawback of mineral oil is its classification as a flammable liquid with low biodegradability, which imposes restrictions on its use and containment in specific environments.

2. Silicone Fluid

Silicone fluid is traditionally selected when a less-flammable liquid is required. It is characterized by a relatively high ignition point, making it well-suited for indoor and vaulted installations. However, silicone has several disadvantages, including a high cost, the production of chemical byproducts, and a lack of biodegradability. It exhibits dielectric strength similar to that of mineral oil but has a higher specific gravity.

3. Hydrocarbon Fluid

Hydrocarbon fluids, which are highly refined petroleum oils, offer fire-resistant properties, making them an ideal choice for applications requiring a less-flammable liquid. These fluids possess excellent insulating and cooling qualities. While they have a lower ignition point than silicone and are more expensive than mineral oil, they share a specific gravity and power factor similar to those of mineral oil and are highly biodegradable.

4. Natural Ester Fluid

Natural ester fluids, typically derived from non-toxic natural oils like soy, are the top choice for environmental considerations due to their complete biodegradability. They are self-extinguishing, making them ideal for indoor installations, and exhibit superior moisture absorption compared to other liquids. Furthermore, natural esters have the highest dielectric strength among common fluids. Their main disadvantages include a higher cost and a higher power factor, which can lead to slightly elevated operating temperatures.

Comparison of Insulating Fluid Types

| Fluid Type | Flammability | Biodegradability | Relative Cost | Key Advantage | Key Disadvantage |

| Mineral Oil | Flammable | Low | Low | Established performance, low cost | Flammable, low biodegradability |

| Silicone | Less Flammable | Lacks | High | High ignition point (indoor use) | High cost, chemical byproducts |

| Hydrocarbon | Fire-Resistant | High | Medium-High | Fire-resistant, highly biodegradable | Lower ignition point than silicone |

| Natural Ester | Self-Extinguishing | Complete | High | Highest dielectric strength, self-extinguishing, superior moisture absorption | Higher cost, higher power factor |

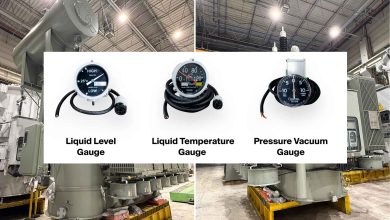

Insulating Liquid Testing and Analysis

Regular maintenance of electrical equipment is paramount for ensuring a long service life. Since the insulating fluid is often considered the “lifeblood” of a liquid-filled apparatus, routine sampling and laboratory analysis are essential. These tests provide critical diagnostic information that may not be detectable through standard electrical tests.

Laboratory tests typically measure the physical and electrical properties discussed above, including dielectric strength, power factor, specific gravity, interfacial tension, and water content. Visual examinations, such as assessing the fluid’s color and transparency, can also provide valuable insights into contaminants and indicate whether electrical arcing has occurred inside the equipment.

Testing standards, such as those specified by the National Electrical Testing Association (NETA) and the American Society for Testing and Materials (ASTM), govern the required analysis. The specific set of tests and parameters are customized based on the apparatus type (e.g., transformers, regulators, oil circuit breakers), voltage class, fluid type, and service age.

Historical Context: Polychlorinated Biphenyls (PCBs)

Polychlorinated biphenyls (PCBs) were historically used in electrical equipment manufactured between 1929 and 1977, primarily due to their non-flammability and excellent insulating properties. However, PCBs have been classified by the U.S. Environmental Protection Agency (EPA) as probable human carcinogens and are associated with various adverse health effects, including neurobehavioral and immunological changes.

Due to these health and environmental risks, the use of PCBs is heavily regulated under the Toxic Substances Control Act (TSCA).

•A “PCB transformer” is defined as one known or assumed to contain PCBs at concentrations greater than 500 parts per million (ppm).

•”PCB-Contaminated Transformers” are those known or assumed to contain between 50 and 499 ppm of PCBs.

All equipment containing PCBs is subject to strict EPA regulations regarding handling, storage, and disposal.