Transformer Diagnostics and Condition Assessment: A Comprehensive Guide

Determining the current condition of power transformers is a critical step in mitigating the risk of catastrophic failure. This guide provides a structured overview of the essential testing and diagnostic techniques used by electrical maintenance professionals to assess transformer health and ensure operational reliability.

The Foundation of Transformer Maintenance

A robust maintenance program relies on thorough, routine inspections that go beyond basic data collection (such as oil levels and temperatures). While Supervisory Control and Data Acquisition (SCADA) systems provide valuable remote monitoring, they cannot replace the nuanced insights gained from physical inspections performed by qualified personnel. Note: Test plans must be customized. Not every test applies to every unit; the specific construction, age, and application of a transformer dictate its unique diagnostic requirements.

Online Diagnostic Testing

Online tests are conducted while the transformer is energized and in service, allowing for real-time health monitoring without interrupting operations.

1. Dissolved Gas Analysis (DGA)

The DGA is the most critical tool for identifying internal abnormalities. By measuring gases dissolved in the insulating oil, it can detect:

- Arcing and partial discharges.

- Overheating of conductors, oil, or the tank.

- Degradation of cellulose (paper) insulation.

- Poor electrical contacts and localized hot spots.

2. Oil Physical and Chemical Analysis

Beyond gas analysis, oil samples are tested for moisture content, acidity, interfacial tension, and the presence of furans or dissolved metals. These metrics indicate the overall aging of the insulation system and potential mechanical issues, such as pump wear.

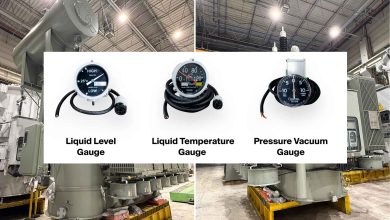

3. Physical and Visual Inspections

Regular external evaluations should focus on:

- Integrity: Identifying oil leaks, broken parts, or compromised support structures.

- Cooling Systems: Checking for radiator blockages and pump malfunctions.

- Auxiliaries: Verifying the accuracy of temperature and level indicators.

- Insulators: Inspecting bushings and lightning arresters for porcelain cracks.

4. Advanced Sensing Technologies

- Infrared (IR) Scanning: Thermographic cameras quickly identify hot spots, circulating currents, and blocked cooling channels.

- Ultrasonic & Sonic Detection: These tools pinpoint internal arcing, partial discharges, and mechanical noises (e.g., loose parts or pump bearing issues).

- Vibration Analysis: Accelerometers detect core vibrations and structural loosening.

- Corona Detection: Specialized scopes identify air ionization at high-voltage connections, often visible during high-humidity conditions.

Offline Diagnostic Testing

Offline tests require the transformer to be de-energized and isolated, providing a deeper look into the integrity of the core and windings.

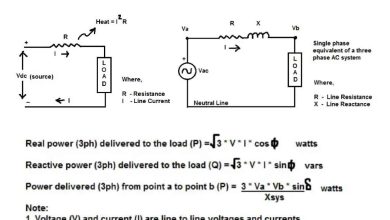

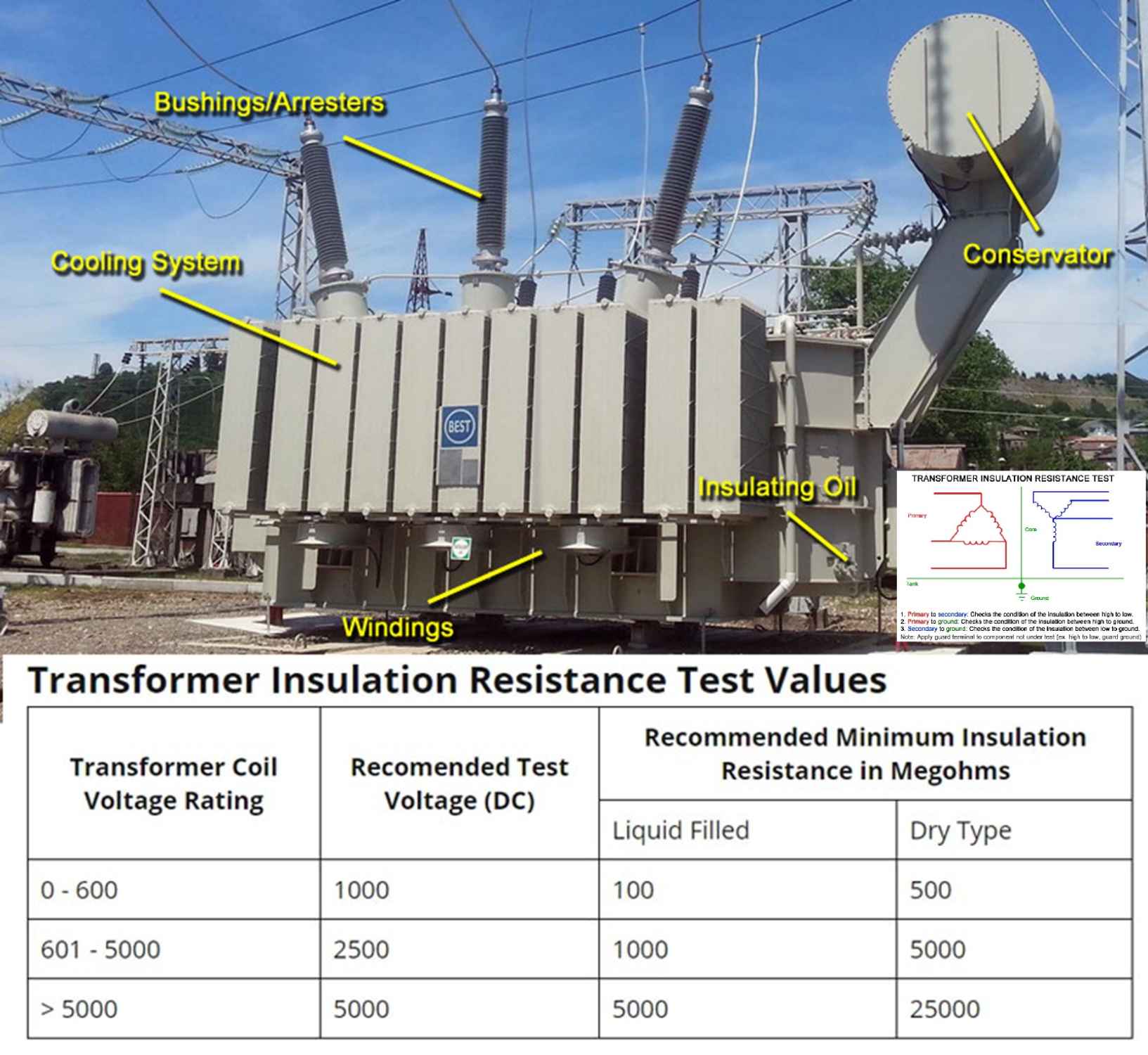

1. Dielectric and Insulation Integrity

- Doble Power Factor Testing: A rising power factor is a primary indicator of insulation deterioration or moisture ingress in windings and bushings.

- Insulation Resistance (PI): The Polarization Index (PI)—the ratio of resistance at 10 minutes versus 1 minute—is a standard benchmark for dielectric strength. Values above 2.0 are generally considered good, while values below 1.0 indicate a high risk of failure.

2. Winding and Core Diagnostics

- Excitation Current: Detects short-circuited turns, core delamination, and tap changer issues.

- Turns Ratio (TTR): Verifies the correct ratio between windings; deviations often signal insulation failure or shorted turns.

- Sweep Frequency Response Analysis (SFRA): Provides a “fingerprint” of the winding structure. It is invaluable for detecting mechanical shifts or damage caused by shipping or through-faults.

- Winding Resistance: Identifies loose connections, broken strands, or high contact resistance in tap changers.

3. Specialized Assessments

- Core-to-Ground Resistance: Used to investigate unintentional core grounds. A healthy service-aged transformer should maintain resistance above 100 megohms.

- Degree of Polymerization (DP): The most accurate method for determining the remaining life of paper insulation. This requires a physical sample and should only be performed if the transformer is already open for other repairs.

Diagnostic Summary by Component

The following table summarizes the primary diagnostic techniques categorized by the transformer component they evaluate:

| Component | Primary Diagnostic Techniques |

| Windings | DC Resistance, TTR, Leakage Reactance, SFRA, Doble Tests, Capacitance |

| Bushings & Arresters | Power Factor, Capacitance, IR Scan, Visual Inspection, Oil Level |

| Insulating Oil | DGA, Dielectric Strength, Moisture, Furans, Acid Number, Interfacial Tension |

| Core | Insulation Resistance, Ground Testing |

| Tanks & Auxiliaries | Fault Pressure/Buchholz Relays, Temperature Indicators, Sound/Vibration Analysis |

| Cooling System | Fan/Pump Rotation, Flow Indicators, IR Scan, Radiator Valve Inspection |