Plant–Grid Interface (PGI): Where Power Plants Are Truly Tested

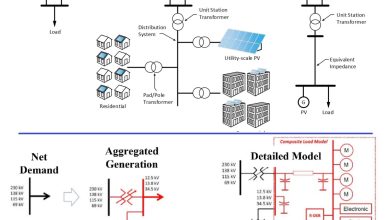

Generating power is a triumph of mechanical and thermal engineering. Connecting that power to a live, dynamic electrical grid is a triumph of electrical and control engineering. The Plant–Grid Interface (PGI) is the critical boundary where many power plants, regardless of their generation technology, discover their real operational and compliance weaknesses. It is the point where technical capability meets regulatory necessity.

The PGI: A Contractual, Electrical, and Operational Handshake

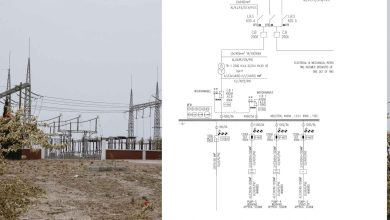

The PGI is far more than a physical connection point on a drawing; it is the contractual, electrical, and operational handshake between a power plant and the Transmission System Operator (TSO). It is the boundary that defines how a power plant must behave, react, and survive when connected to the grid. Crucially, at the PGI, the grid does not adapt to the plant—the plant must adapt to the grid. The requirements imposed at the PGI are formalized in the Grid Code, a set of technical specifications designed to ensure the stability and reliability of the entire power system. These requirements cover a wide range of operational parameters:

| PGI Requirement | Technical Focus | Operational Goal |

| Voltage and Frequency Limits | Continuous operation within defined voltage and frequency bands. | Preventing unnecessary disconnections during minor fluctuations. |

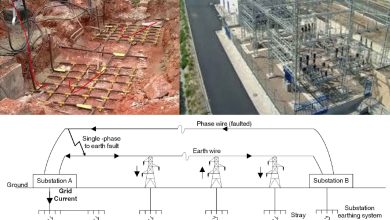

| Fault Ride-Through (FRT) | Ability to remain connected during temporary voltage dips (LVRT) or swells (HVRT) caused by faults. | Maintaining system stability and preventing cascading grid collapse. |

| Reactive Power & Power Factor Control | Provision of leading and lagging reactive power (Mvar) to support grid voltage. | Dynamic voltage support and maintaining system power quality. |

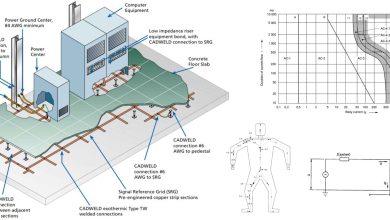

| Protection Coordination | Ensuring the plant’s protection schemes are selective and coordinated with the grid’s protection. | Isolating only the faulted section without tripping the entire plant. |

| Synchronization Rules | Strict adherence to voltage, frequency, and phase angle matching before connection. | Preventing severe mechanical and electrical stress on equipment. |

Why PGI Is Bigger Than a Substation

While a substation is the physical infrastructure that transfers power, the PGI governs permission—the right to export power onto the grid. If PGI requirements are not met, the consequences are immediate and severe:

- Power Export is Limited or Blocked: Non-compliant plants may be denied their “Permit to Operate” or have their output curtailed.

- Revenue Drops Quietly: Plants are forced to run below capacity or trip offline during disturbances, resulting in significant, often unbudgeted revenue loss.

- Loss of Grid Trust: Grid operators rely on predictable plant behavior. A history of non-compliance or tripping during faults erodes trust, potentially leading to stricter operational mandates.

Many plants are technically sound in their generation capacity but are ultimately grid-noncompliant. Their inability to dynamically support the grid during disturbances—a requirement that has become increasingly stringent with the rise of renewable energy—is their Achilles’ heel.

Common PGI Mistakes and Strategic Avoidance

The most significant PGI failures often stem from a lack of strategic foresight and interdisciplinary coordination. The grid is a dynamic, frequently unstable network, and PGI design must be realistic rather than based on ideal steady-state assumptions.

| Common PGI Mistake | Strategic Avoidance |

| Treating PGI as only a protection issue | Recognize PGI as a holistic issue involving protection, control, SCADA communication, and commercial compliance. |

| Ignoring grid code updates until commissioning | Integrate grid code compliance verification (GCC) into the design phase, using modeling and simulation to predict performance. |

| Poor coordination between teams | Establish a dedicated PGI team that bridges the gap between electrical design, control system programming, and operational procedures. |

| Weak voltage and reactive power control strategy | Implement a robust control system capable of dynamic reactive current injection to support voltage during faults (FRT). |

| Assuming steady grid conditions | Design the plant to handle realistic grid instability, including transient overvoltages and frequency excursions. |

What Good PGI Design Looks Like

A strong PGI design transforms a power plant from a passive energy source into an active, supportive grid participant. This is where engineering maturity truly shows. A compliant and robust PGI allows a plant to:

- Stay Connected During Grid Disturbances: Utilizing advanced Fault Ride-Through (FRT) capabilities to weather temporary voltage and frequency deviations.

- Support Voltage Instead of Collapsing It: Dynamically injecting reactive current to help stabilize the grid during a fault is a key requirement for modern grid codes.

- Recover Smoothly After Faults: Returning to pre-fault active power output quickly and predictably.

- Communicate Clearly: Maintaining reliable, real-time data exchange (SCADA) with the system operator for dispatch and monitoring.

- Earn Long-Term Grid Confidence: Establishing a track record of reliable, supportive operation, which is invaluable for future contract negotiations and operational flexibility.

The Quiet Truth About PGI

The ultimate paradox of the Plant–Grid Interface is that it does not announce itself when done right. A perfectly compliant plant operates seamlessly, its stability taken for granted. But when done wrong, the PGI becomes a persistent, noisy problem that shuts plants down repeatedly, limits revenue, and damages professional reputation. Power generation gets the applause, but the PGI decides whether that power is accepted. Understanding this critical boundary is essential for every professional involved in the design, construction, and operation of modern power facilities.

References

[1] NERC. Fault Ride-Through (FRT) Requirements. Defines the mandated ability of generating units to remain connected during grid disturbances.

[2] DNV. Grid Code Compliance Verification. Outlines the critical phase of modeling, simulation, and field testing required for final commissioning approval.