Top Electrical Panel Mistakes to Avoid: A Guide for Engineers and Technicians

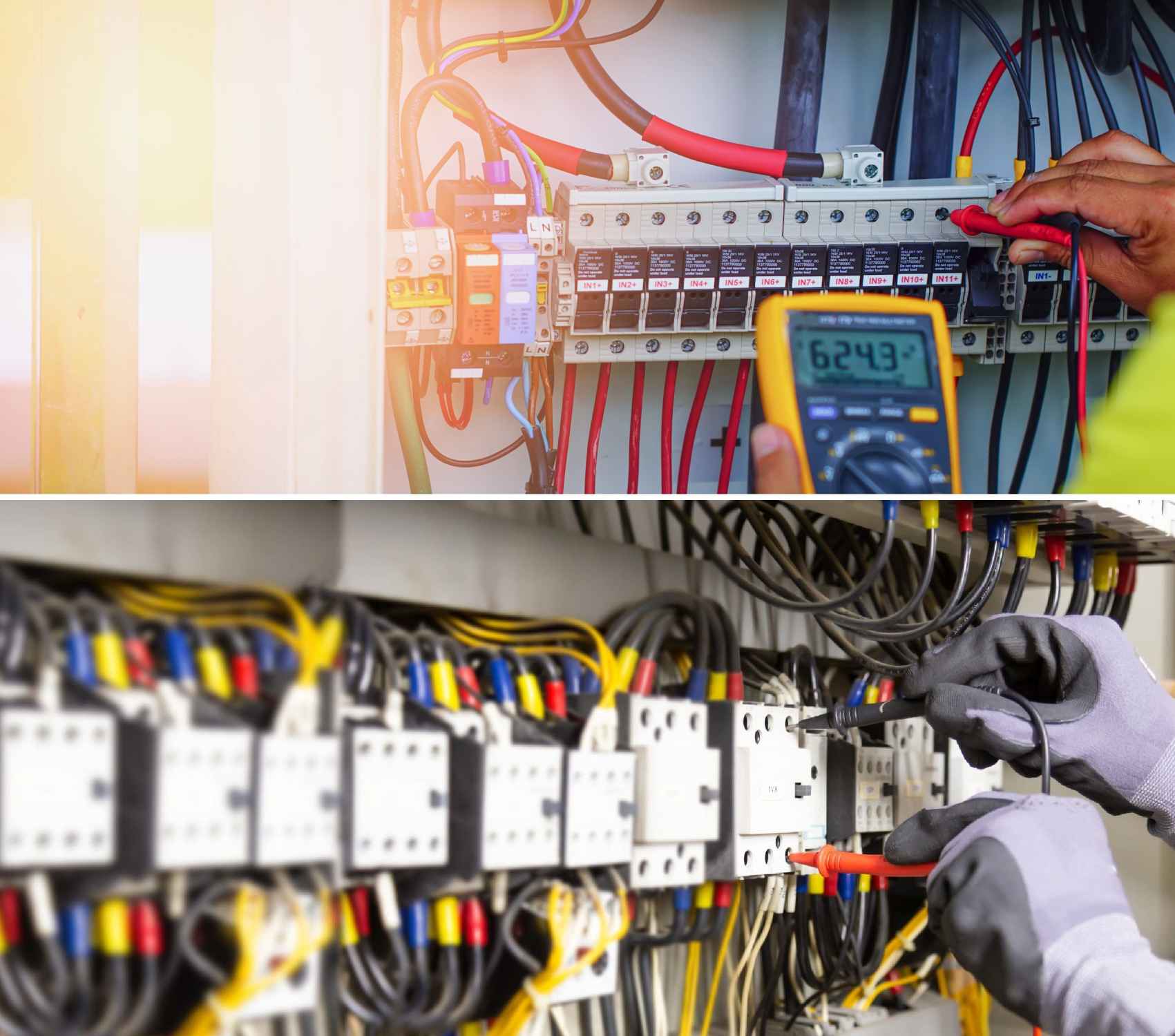

Electrical panel work often appears deceptively straightforward, yet the consequences of small errors can escalate into costly disasters, equipment failure, or severe safety hazards. The integrity of an entire electrical system hinges on meticulous attention to detail during installation, maintenance, and inspection. Even experienced engineers and technicians can overlook critical steps, transforming minor oversights into significant liabilities.

Here are the top mistakes every professional should actively watch out for, categorized by their impact on safety, compliance, and long-term reliability.

I. Safety and Compliance Errors

1. Overlooking Proper Clearance (NEC 110.26)

The National Electrical Code (NEC) mandates specific workspaces around electrical equipment to ensure personnel safety and maintenance access. Inadequate working clearance is a frequent violation that compromises both safety and equipment longevity. Panels require enough space for airflow, heat dissipation, and, most critically, for personnel to safely operate and troubleshoot the equipment while minimizing arc flash risk.

The NEC Section 110.26 requires three critical dimensions for working space:

•Depth: A minimum of 36 inches (3 feet) for systems up to 600V.

•Width: At least 30 inches or the width of the equipment, whichever is greater.

•Height: A minimum of 6.5 feet (78 inches) or the height of the equipment.

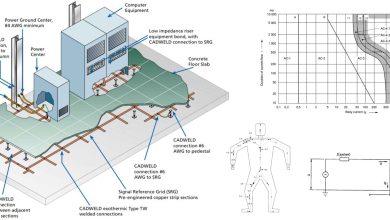

2. Poor Grounding Connections

The grounding and bonding system is the cornerstone of electrical safety. One weak ground connection can compromise the entire system, preventing fault current from safely returning to the source and clearing the circuit. This failure puts personnel at severe risk of electric shock and can damage equipment. Technicians must always verify the continuity and low impedance of the grounding path, ensuring all connections are clean, secure, and tested.

3. Improper Torqueing of Connections

The tightening of terminals is a mechanical detail with profound electrical consequences. Loose or over-tightened terminals are a leading cause of faults and burnouts.

•Under-torqueing creates high resistance at the connection point, leading to excessive heat generation, which can melt insulation and cause fires.

•Over-torqueing can damage the terminal lug, conductor strands, or the internal components of the breaker, leading to mechanical failure and intermittent faults.

Since the 2017 edition, the NEC has emphasized the use of a calibrated torque wrench whenever the equipment manufacturer specifies a tightening torque. Following these specifications is non-negotiable for maintaining low resistance and long-term connection integrity.

II. Operational and Reliability Errors

4. Wrong Wire Sizing

Using the wrong gauge wire—either too small or too large—is a fundamental error. Undersized conductors cause overheating, excessive voltage drop, and fire hazards, as they cannot safely carry the required current (ampacity). Conversely, oversized conductors can be challenging to terminate properly, leading to the torqueing issues mentioned above. Engineers and technicians must strictly adhere to the ampacity tables (e.g., NEC Table 310.16) and ensure the conductor’s temperature rating is compatible with the equipment’s terminal rating (typically 75°C).

5. Incorrect Labeling of Circuits

Mislabeling or illegible labeling of circuits is a common, yet critical, mistake. It leads to confusion, significantly delays troubleshooting, and poses a direct safety hazard during maintenance. Every circuit and every modification must be legibly identified with its clear, evident, and specific purpose or use, as required by NEC 408.4. Always double-check every tag and ensure the panel directory accurately reflects the installed system.

6. Mixing Old and New Components Without Testing Compatibility

In system upgrades or repairs, simply replacing a component is not enough. Mixing old and new components without verifying compatibility can cause short circuits, equipment damage, or failure to trip under fault conditions. This is particularly true for circuit breakers, where using unlisted or “alien” breakers in a panelboard is a direct violation of NEC 110.3(B) and can result in poor busbar contact and catastrophic failure.

III. Maintenance and Longevity Errors

7. Ignoring Environmental Factors

The environment in which a panel operates dictates its longevity. Moisture, dust, or high temperatures can rapidly degrade components. Choosing an enclosure with the incorrect NEMA or IP rating for the location (e.g., NEMA 1 in a damp or dusty area) will lead to corrosion and premature failure. Furthermore, high ambient temperatures can derate the ampacity of conductors, requiring a larger wire size than would be necessary in a cooler environment.

8. Rushing Inspections and Testing

The pressure to complete a job quickly often leads to rushing inspections and testing. Skipping tests, such as insulation-resistance checks, continuity checks, or thermal-imaging surveys, can hide faults that will inevitably become costly failures later. A comprehensive, unhurried inspection is the final quality control step that verifies every function and connection is secure and compliant.

9. Neglecting Documentation

A panel installation is incomplete without thorough documentation. Neglecting to update schematics, wiring diagrams, and maintenance logs turns future troubleshooting into a nightmare for subsequent technicians. Proper documentation, including “as-built” drawings and a log of all modifications, is essential for maintaining the system’s integrity and ensuring safe, efficient operation over its lifespan.

Conclusion

Attention to small details is everything in electrical work. While the points above represent the most common pitfalls, they are all preventable through careful planning, adherence to codes, and a commitment to quality control. By prioritizing proper clearance, meticulous torqueing, and comprehensive documentation, engineers and technicians can significantly enhance the safety, reliability, and lifespan of any electrical panel installation.

References

[1] National Fire Protection Association (NFPA). NFPA 70: National Electrical Code (NEC). Section 110.26, Spaces About Electrical Equipment.

[2] National Fire Protection Association (NFPA). NFPA 70: National Electrical Code (NEC). Section 110.14(D), Terminal Connection Torque.

[3] National Fire Protection Association (NFPA). NFPA 70: National Electrical Code (NEC). Section 408.4, Circuit Directory.