Troubleshooting and Repair of Motor Starters

Abstract

Motor starters play a vital role in the safe and reliable operation of electric motors in industrial and commercial installations. Failures in motor starter circuits can result in equipment damage, production losses, and safety hazards. This article presents a structured and academic overview of common motor starter faults, their underlying causes, and systematic diagnostic and corrective measures. Emphasis is placed on proper measurement techniques, fault isolation, and adherence to electrical safety standards.

1. Introduction

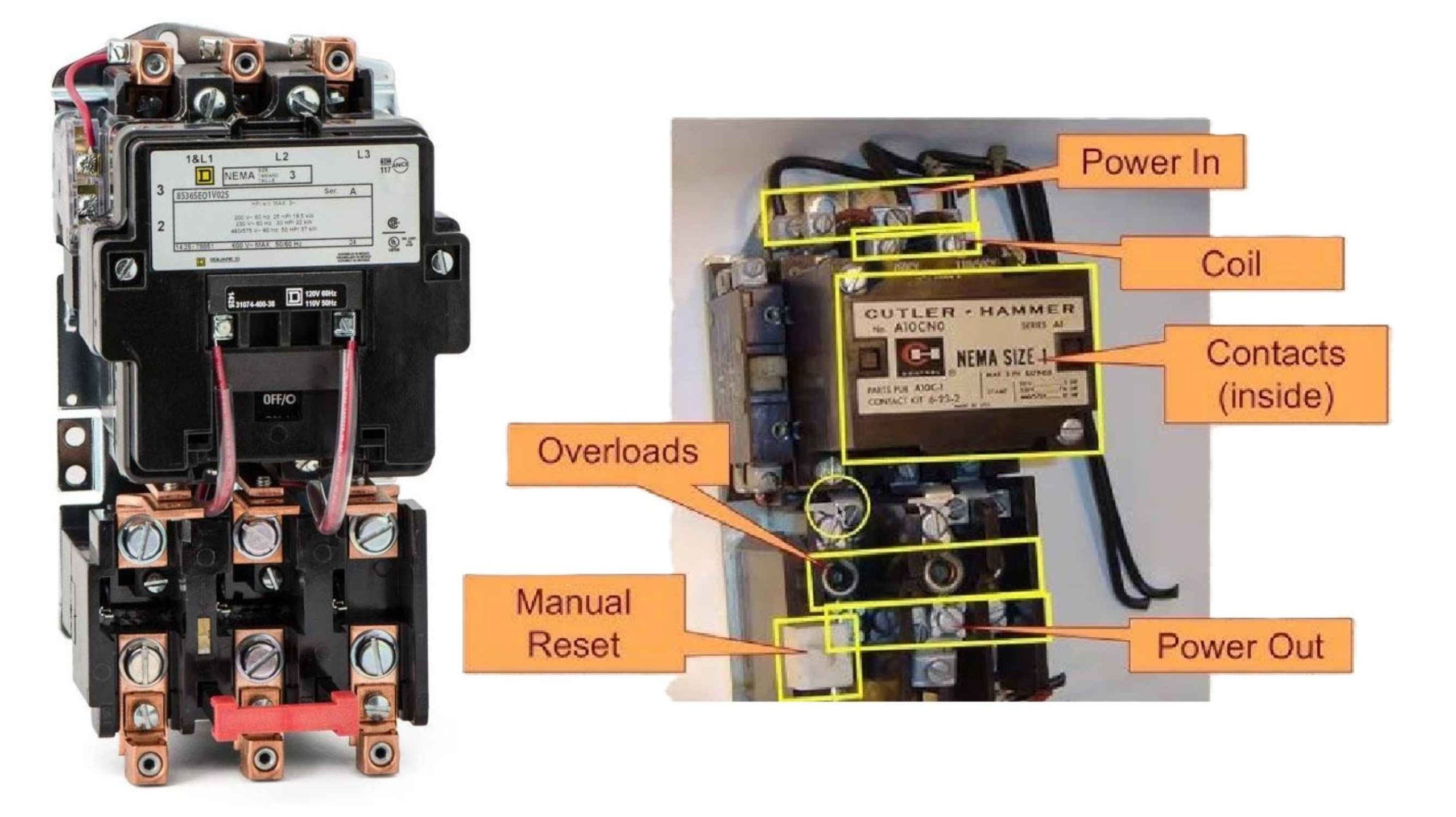

Electric motors are commonly controlled through motor starters that provide switching, protection, and control functions. A typical motor starter consists of a contactor, overload relay, control devices (pushbuttons, sensors, interlocks), and protective elements such as fuses or circuit breakers. Due to electrical, mechanical, and environmental stresses, motor starters are prone to various operational failures. Systematic troubleshooting is essential to restore functionality while ensuring personnel and equipment safety.

2. Motor Not Starting at All

2.1 Possible Causes

- Absence of power supply due to blown fuses or tripped circuit breakers

- Defective start pushbutton or control switch

- Open or damaged contactor coil

- Loose wiring, broken terminals, or poor electrical connections

2.2 Diagnostic and Corrective Measures

- Measure supply voltage using a calibrated multimeter

- Inspect and replace blown fuses; reset or replace circuit breakers as required

- Perform continuity testing on the start pushbutton

- Measure the contactor coil resistance to verify that it is not open-circuit

- Tighten loose terminals and repair or replace damaged conductors

3. Contactor Not Pulling In

3.1 Possible Causes

- Contactor coil not receiving energizing voltage

- Missing or incorrect control voltage

- Faulty overload relay auxiliary contact

- Control circuit interlocks (safety switches, limit switches, sensors) are not satisfied

3.2 Diagnostic and Corrective Measures

- Systematically trace the control circuit using a multimeter

- Verify that the start command reaches the contactor coil terminals

- Temporarily bypass the overload relay contact for testing purposes only

- Replace defective contactor coils or faulty control relays

4. Starter Tripping Immediately After Starting

4.1 Possible Causes

- Overload relay setting lower than the motor’s full-load current

- Excessive motor current due to mechanical overloading

- Phase loss or phase imbalance in three-phase systems

- Loose, damaged, or overheated power cables

4.2 Diagnostic and Corrective Measures

- Adjust the overload relay setting in accordance with the motor nameplate full-load amperes (FLA)

- Inspect the driven load for mechanical jamming or abnormal friction

- Measure the current in each phase and compare the values for imbalance

- Tighten loose connections and replace damaged or burnt cables

5. Starter Energized but Motor Fails to Rotate

5.1 Possible Causes

- Single phasing in three-phase motors

- Mechanical binding within the motor or connected load

- Failure of start or run capacitors in single-phase motors

5.2 Diagnostic and Corrective Measures

- Verify the presence and balance of three-phase voltage at motor terminals

- Inspect the motor shaft, bearings, and coupling for mechanical obstruction

- Test and replace defective start or run capacitors as necessary

6. Starter Buzzing or Excessive Arcing

6.1 Possible Causes

- Worn, pitted, or contaminated contactor contacts

- Undervoltage conditions are causing incomplete contactor closure

- Partially shorted or deteriorated contactor coil

6.2 Diagnostic and Corrective Measures

- Inspect contactor contacts and clean or replace if excessive wear is observed

- Measure supply and control voltage stability under load

- Replace contactor coils exhibiting abnormal heating or insulation failure

7. Starter Fails to Stop When Stop Command Is Issued

7.1 Possible Causes

- Stuck or defective stop pushbutton

- Welded or mechanically jammed contactor contacts

- Faulty control logic, programmable logic controller (PLC), or human–machine interface (HMI)

7.2 Diagnostic and Corrective Measures

- Test stop pushbutton contacts for correct normally-closed operation

- Manually verify the mechanical disengagement of the contactor

- Replace welded contactors or repair faulty control logic devices

8. Importance of Field Instruments and Interlocks

Field instruments such as pressure switches, limit switches, and safety interlocks play a critical role in motor control systems. A single faulty sensor or failed safety device can prevent motor operation or cause unexpected shutdowns. Therefore, these components must be included in any comprehensive troubleshooting procedure.

9. Safety Considerations

All troubleshooting and repair activities must be performed in accordance with established electrical safety standards. Power sources should be isolated, and Lockout–Tagout (LOTO) procedures must be strictly followed. Appropriate personal protective equipment (PPE) should be used at all times to minimize the risk of electrical shock and arc flash hazards.

10. Conclusion

An academic and systematic approach to troubleshooting motor starters enhances reliability, safety, and equipment longevity. By understanding common failure modes, applying structured diagnostic methods, and adhering to safety practices, engineers and technicians can efficiently identify faults and implement practical corrective actions in motor control systems.