Low Voltage and Medium Voltage Fuses: Types, Applications, and Protection Strategies

Fuses are among the most fundamental protective devices in electrical power systems. Acting as the first line of defense, they protect equipment from overcurrents, short circuits, and electrical faults that can cause severe damage, downtime, or even fire hazards.

Depending on system voltage levels, fuses are broadly categorized into:

- Low Voltage (LV) fuses

- Medium Voltage (MV) fuses

Both play critical roles across industrial plants, commercial facilities, and utility distribution networks—protecting transformers, motors, switchgear, and feeders.

What Is a Fuse?

A fuse is a protective device containing a metal element that melts when excessive current flows through it. Once the element melts, the circuit opens, preventing further current flow and protecting downstream equipment.

Fuses are classified based on:

- Voltage rating

- Interrupting rating (AIC)

- Application type

- Construction design

Let’s explore the major categories.

Low Voltage (LV) Fuses

Low-voltage fuses are typically used in systems up to:

- 1,000V AC

- 1,500V DC

They are widely applied in control panels, motor circuits, distribution boards, and automotive systems.

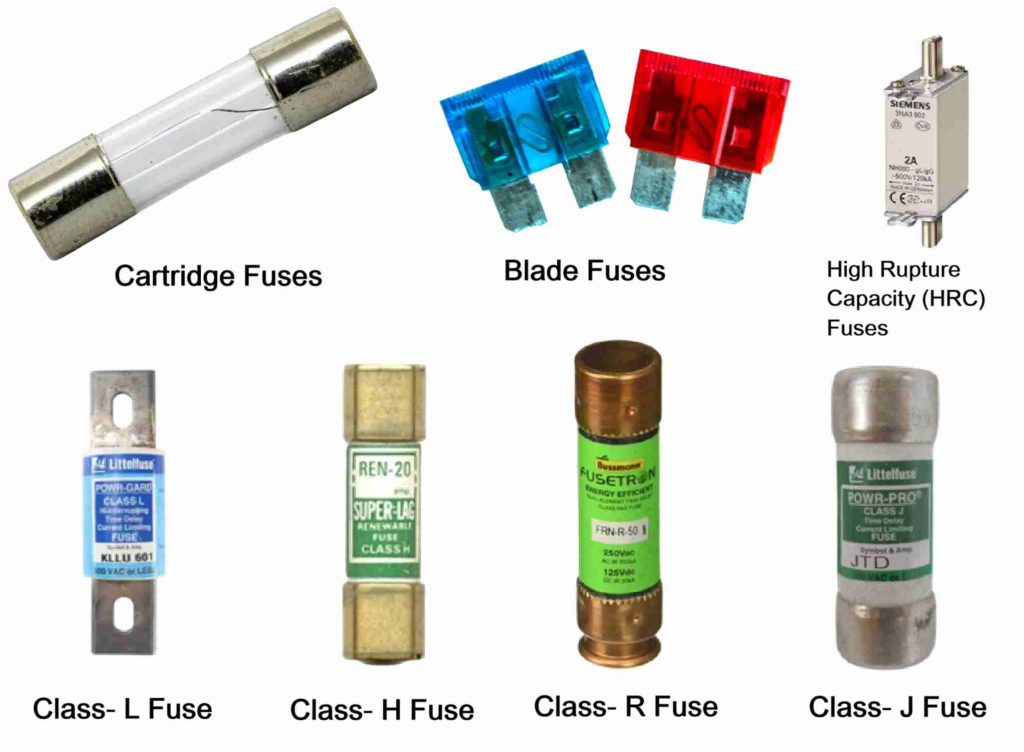

Common Types of LV Fuses

1. Cartridge Fuses

Cartridge fuses consist of a cylindrical body with metal end caps that connect to a fuse holder.

They are available in:

- Fast-acting versions – clear faults instantly

- Time-delay versions – allow temporary inrush currents (e.g., motor starting)

Applications:

- Industrial control circuits

- Motor protection

- Power distribution systems

Their reliability and ease of replacement make them one of the most widely used LV fuse types.

2. Blade Fuses

Blade fuses are compact plug-in fuses commonly used in automotive DC systems. They feature a plastic housing with two metal prongs.

Key features:

- Color-coded by amp rating

- Available in fast-acting and slow-blow versions

- Easy installation and replacement

Applications:

- Automotive circuits

- Low-voltage electronics

- Control systems

They protect components such as headlights, wipers, and vehicle electronics.

3. High Rupturing Capacity (HRC) Fuses

High Rupturing Capacity (HRC) fuses are designed to safely interrupt high fault currents without explosion or damage.

Construction:

- Ceramic or glass enclosure

- Filled with arc-quenching material (typically silica sand)

Applications:

- Manufacturing plants

- Power plants

- Large commercial facilities

- Switchgear panels

Their high breaking capacity makes them ideal for protecting expensive machinery and minimizing downtime.

UL-Classified Low Voltage Fuses

Under Underwriters Laboratories (UL) standards, LV fuses are further classified based on performance and application.

Class L Fuses

- 600V rating

- 601A–6000A current range

- 200 kA interrupting capacity

Used for:

- Switchboard mains

- Large motor circuits

- Main service entrances

Designed for very high-current industrial applications.

Class H Fuses

- 250V or 600V rating

- 10 kA interrupting capacity

- Non-current limiting

Due to their relatively low interrupting rating, they are now largely replaced by higher-performance classes in modern systems.

Class R Fuses (RK1 & RK5)

- 250V or 600V

- 200 kA interrupting capacity

- Current-limiting design

Types:

- RK1 – Superior current-limiting performance

- RK5 – General-purpose motor and feeder protection

They include a rejection feature to prevent replacement with lower-rated Class H fuses.

Class J Fuses

- 600V rating

- 200 kA interrupting capacity

- Compact, current-limiting

Applications:

- Motor Control Centers (MCCs)

- Industrial switchgear

- Transformer protection

Their space-saving design and high performance make them popular in high-reliability systems.

| es | Construction/Design | Voltage Rating | Ampere Range | AIC | Applications | Key Features |

|---|---|---|---|---|---|---|

| Cartridge Fuse | Cylindrical body with metal end caps | Up to 1,000V AC / 1,500V DC | Wide range (few hundreds) | 10–100 kA (typical) | Industrial control, motors, distribution | Available in fast-blow and time-delay types |

| Blade Fuse | Plastic body with two prongs | 12–32V DC (Automotive) | 1–40A | 1–2 kA | Automotive circuits, electronics | Color-coded, compact, easy replacement |

| HRC Fuse | Ceramic/glass body with silica filling | Up to 1,000V | Up to 800A | 80–120 kA | Industrial, commercial, switchgear | High breaking capacity, arc-quenching |

| Class L | Heavy-duty, current limiting | 600V | 601–6000A | 200 kA | Main services, switchboards | Used in high-current circuits |

| Class R (RK1 / RK5) | Current-limiting, rejection type | 250V / 600V | 1–600A | 200 kA | General protection, motor circuits | RK1 = higher performance, RK5 = general-purpose |

| Class H | Non-current limiting | 250V / 600V | 1–600A | 10 kA | Non-critical applications | Obsolete in many cases |

| Class J | Compact, current limiting | 600V | Up to 600A | 200 kA | MCCs, transformers, panels | Wide range (a few hundred) |

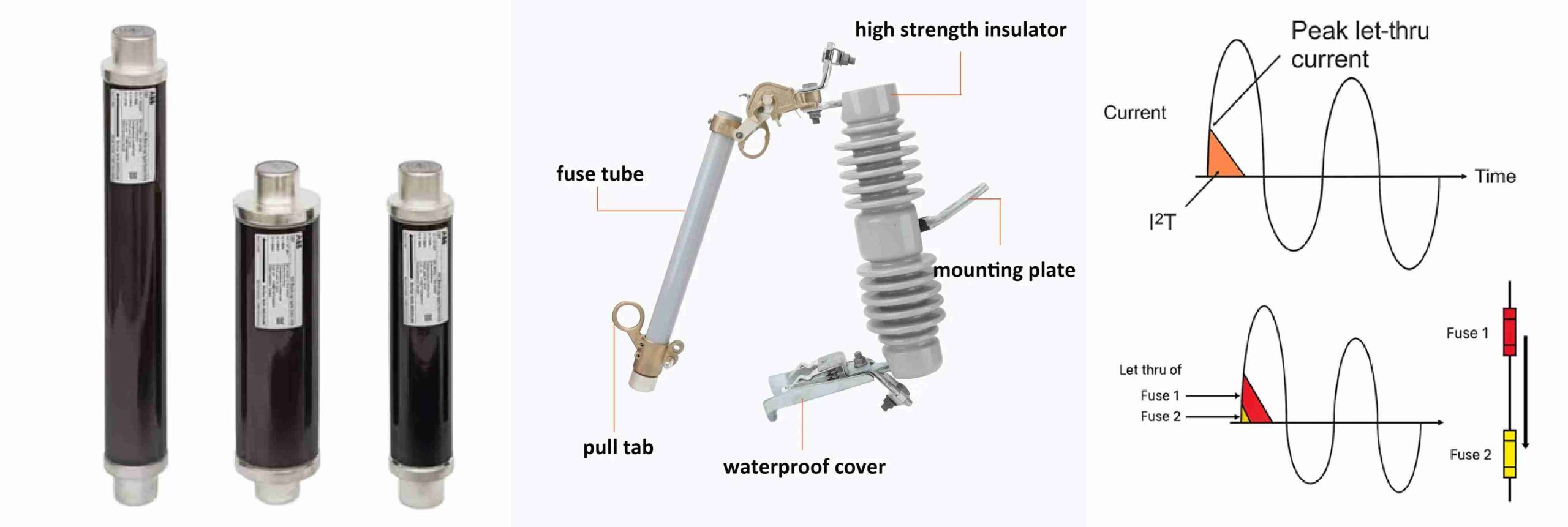

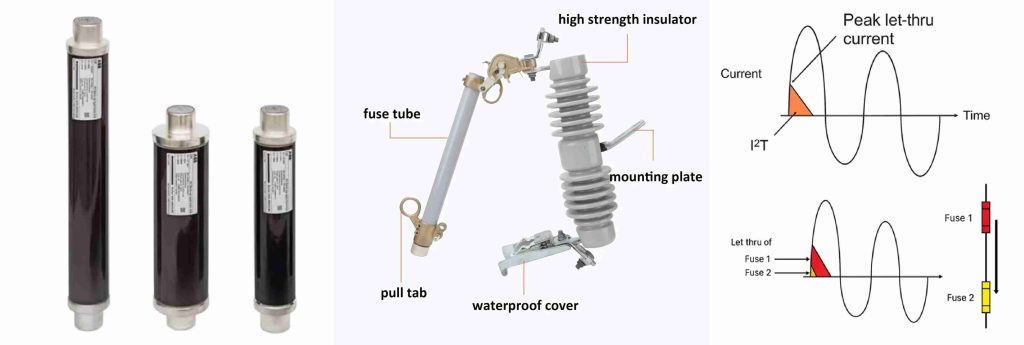

Medium Voltage (MV) Fuses

Medium voltage fuses operate in systems ranging from 1 kV to 36 kV.

They are used for:

- Utility transformers

- MV motors

- Switchgear

- Feeder protection

MV fuses must handle significantly higher energy levels than LV fuses.

Expulsion (Drop-Out) Fuses

Expulsion fuses are non-current-limiting devices that extinguish arcs using gas-expelling mechanisms.

When a fault occurs:

- The fuse element melts

- Gas forms inside the fuse

- The arc is expelled and extinguished

Applications:

- Overhead distribution lines

- Pole-mounted transformers

They are cost-effective but require periodic maintenance.

MV Performance-Based Fuse Ratings

MV fuses are categorized by ANSI performance classifications.

E-Rated Fuses (Power Fuses)

Used primarily for:

- Transformer protection

- Feeder circuits

- General MV equipment

They provide full-range protection and operate within defined time-current parameters in accordance with ANSI standards.

For example:

- 100E and below must open within 300 seconds at 200–240% current

- Above 100E must clear within 600 seconds at 220–240% current

They are widely used in utility transformer protection.

R-Rated Fuses

Designed specifically for:

- Medium voltage motors

- Motor controllers

They are current-limiting and time-delay types.

An R-rated fuse:

- Must open within 15–35 seconds

- When exposed to 100× its R rating

This allows the fuse to tolerate motor inrush current while still protecting against short circuits.

Current-Limiting Fuses (CLF)

Current-limiting fuses interrupt fault current extremely quickly—typically within a quarter cycle and before the first current peak.

They:

- Reduce peak let-through current (Ip)

- Minimize thermal energy (I²t)

- Lower mechanical stress on equipment

- Reduce arc flash energy

Available in both LV and MV applications:

- Up to 200 kA (LV)

- 63 kA or higher (MV)

Their fast operation makes them essential in:

- Critical infrastructure

- Industrial plants

- High-density power systems

Series-Rated Fuse Systems

Series-rated configurations combine two protective devices—typically a fuse and a circuit breaker—in series.

In this setup:

- The upstream device clears high fault currents

- The downstream device handles lower-level faults

This layered protection approach:

- Improves system reliability

- Enhances coordination

- Prevents cascading failures

- Optimizes cost and protection performance

| Category | Type | Construction / Design | Voltage Rating | Ampere Range | AIC | Applications | Key Features |

|---|---|---|---|---|---|---|---|

| Medium Voltage (MV) | Expulsion Fuse | Arc-expelling (gas release), open vent | 1–36 kV | Depends on use (typically 1–200 A) | Non-current limiting (lower) | Overhead lines, pole transformers | Cost-effective; requires periodic maintenance |

| E-Rated Fuse | Current-limiting, full-range | 2.4–34.5 kV | 1E–200E+ | Up to 63 kA | Transformers, feeder protection | Time-dependent response; good transformer protection | |

| R-Rated Fuse | Time-delay, current-limiting | 2.4–15.5 kV | 2R–24R+ | 50–63 kA | MV motor protection | Designed to delay through motor inrush currents |

Role of Fuses in Power System Studies

Fuses significantly influence engineering studies, such as:

1. Short Circuit Studies

Fuses must be rated to interrupt the maximum available fault current safely. Incorrect ratings can result in equipment failure or catastrophic damage.

2. Arc Flash Studies

Current-limiting fuses drastically reduce incident energy by clearing faults in less than half a cycle, thereby lowering arc-flash hazard levels and improving worker safety.

3. Protection Coordination Studies

Engineers use Time-Current Characteristic (TCC) curves to ensure selective coordination. Proper fuse selection ensures:

- Only the closest protective device operates

- Minimal system disruption

- Stable system performance

Final Thoughts

Low-voltage and medium-voltage fuses are indispensable components of modern electrical systems. Whether protecting a control panel, motor circuit, transformer, or distribution feeder, fuses provide fast, reliable, and cost-effective protection.

Their ability to:

- Interrupt dangerous fault currents

- Limit arc flash energy

- Support protection coordination

- Prevent equipment damage

makes them essential for maintaining system stability, operational continuity, and personnel safety in industrial, commercial, and utility power systems. Understanding fuse types, ratings, and applications is key to designing a safe and resilient electrical power system.