Electrical testing has been around for many years, testing whether electrical equipment functions correctly and safely. Usually, a fixed-voltage or current signal is applied, and a simple response is measured, such as resistance, continuity, or insulation value. However, with newer electrical tools and sophisticated computer technologies, the modern electrical testing methods have become far more advanced. These methods involve multiple tests across various stages, differences in testing parameters, and advanced data analysis. In other words, it leads to a better diagnosis and predictive maintenance of an apparatus, or it may not. This article presents various sophisticated electrical testing methods and the modern test instruments technicians use to perform accurate, rapid field analysis.

1. Insulation Resistance Profile (IRP)

An IRP is a visual representation of how the resistance of insulation systems changes over time. In most instances, a resistance measurement on a given body is taken at specific intervals – say every 5 seconds – for a particular duration – usually 10 minutes. The resulting data can be used to determine the condition of the insulation system, which generally falls within one of 4 profiles:

- Normal: Indicates healthy insulation with no significant issues.

- Moisture: Suggests the presence of moisture within the insulation material.

- Contamination: Points to impurities or foreign materials affecting insulation performance.

- Embrittlement: Reflects aging or degradation that makes the insulation brittle and less effective.

Additionally, when the insulation resistance exceeds 5000 megohms, the IRP may reveal subtle characteristics that could otherwise go unnoticed, offering further insights into the insulation’s condition.

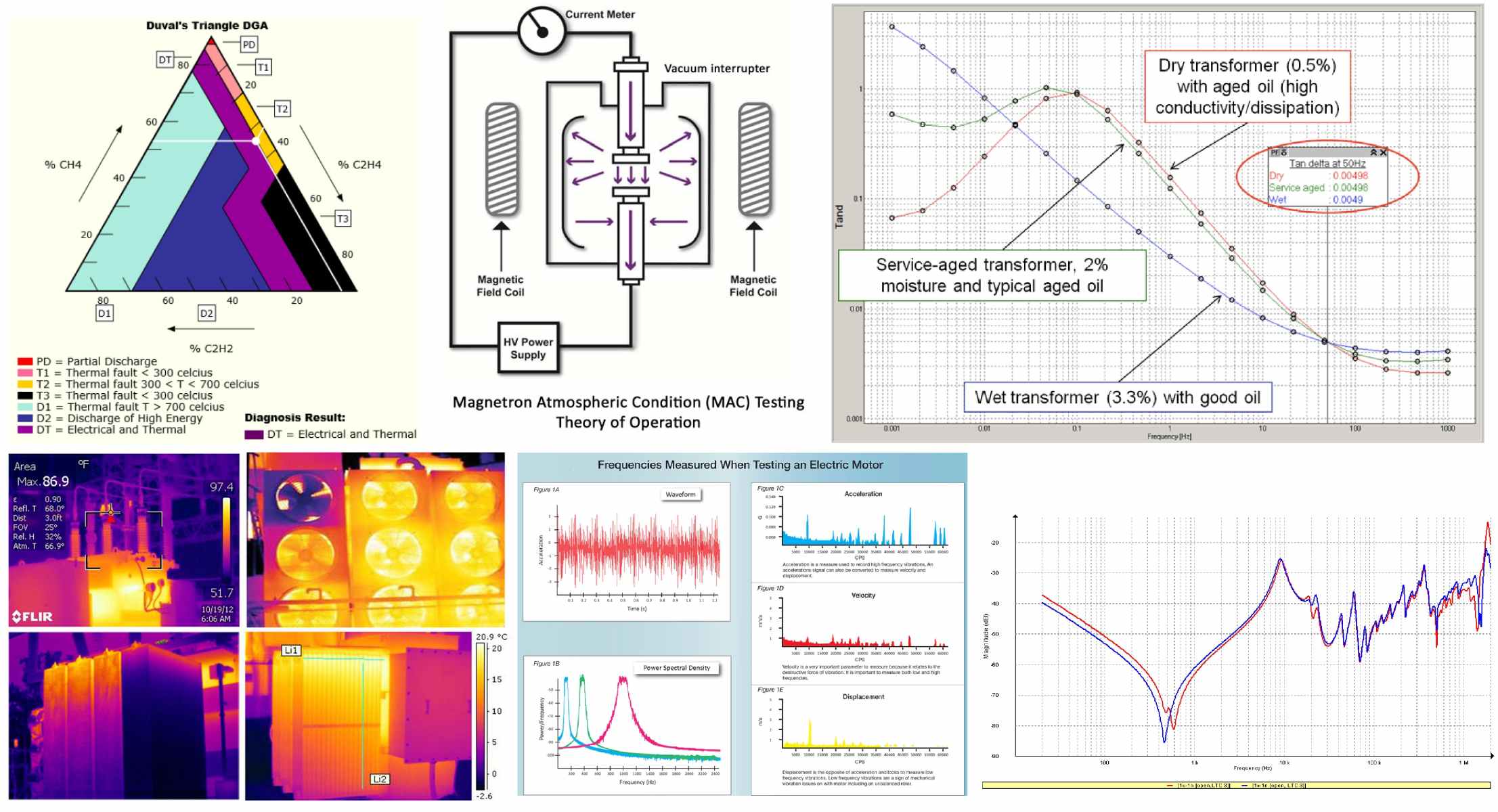

2. Sweep Frequency Response Analysis (SFRA)

Sweep Frequency Response Analysis, a.k.a. SFRA, is an advanced diagnostic method used to assess the mechanical and electrical integrity of windings containing equipment like transformers and reactors. This technique sends a signal through different frequencies into the windings. It also measures the response signal that comes back. Test results can be compared to reference points, such as the original baseline tests run when the equipment was new or previous tests on the equipment. Comparing the present state to the last survey shore report helps identify problems such as mechanical damage, physical deformation, or electrical changes in the winding.

SFRA is a versatile tool used in various scenarios, including:

- Baseline Testing: Establishing a reference for new transformers.

- Routine Diagnostics: Monitoring equipment condition during regular maintenance.

- Post-Fault Testing: Assessing potential damage following a system fault or incident.

By identifying subtle changes, SFRA allows for early detection of problems, reducing the risk of unexpected equipment failures.

3. Dielectric Frequency Response (DFR)

Dielectric Frequency Response or Frequency Domain Spectroscopy is a non-destructive diagnostic method for assessing the insulation condition of power transformers, cables, and other electrical equipment. This method determines the dielectric losses and the material’s capacitance over different frequencies. DFR works well for assessing insulation health and estimating moisture content within the system. The procedure begins with dielectric measurements of the material and comparing them to a hypothetical model. This process will allow us to determine critical parameters such as moisture content and oil conductivity. The results of DFR testing are typically presented as curves that plot:

- Capacitance

- Dissipation Factor (Tan δ)

- Power Factor

The insulation performance under different electrical conditions is presented in a graph showing the values as a function of frequency. Through DFR, technicians can assess insulation systems for moisture, aging, or contamination and arrive at reliable diagnostic and maintenance decisions.

4. Electromagnetic Signature Analysis (EMSA)

EMSA is a diagnostic technique similar to power quality analysis, but it involves a different method of data collection. Instead of connecting to each energized phase conductor, EMSA employs a single split-core RFCT (Radio Frequency Current Transformer) placed around the power conduit, ground, or neutral lead of the equipment under test. This technique captures radio signals emitted by electrical devices. The EMSA signature is the fingerprint providing information to pinpoint the specific physical location of the defect in the system. The data will not require any direct connection to the equipment; it will be obtained through electromagnetic coupling. EMSA signatures contain characteristic patterns of different anomalies that vary in frequency and amplitude. These patterns can include phenomena such as:

- Corona Discharge

- Arcing

- Radio Signals

- Random Noise

- Electronic Transients

Computers analyze the data we collect, either with the help of human engineers or through machine learning algorithms. This allows for a precise assessment of the problems with the unique EMSA signature. Data is collected according to the international standard CISPR16, i.e. standard for measuring radio disturbance voltages and currents in the frequency range 9 kHz to 1 GHz. It helps achieve accurate, consistent diagnoses.

5. Magnetron Atmospheric Condition (MAC) Test

Historically, they are tested in the field using a high-potential (hi-pot) test to determine their dielectric strength. In this technique, a voltage is applied across the open contacts, and the leakage current is measured. Hi-pot testing can effectively identify immediate failures; however, it only provides a simple pass/fail result. Additionally, hi-pot testing cannot determine if the vacuum inside the gas has dropped to a critical failure point. On the other hand, the Magnetron Atmospheric Condition (MAC) test is a more sophisticated and predictive test for vacuum interrupters. It helps you determine the vacuum leak rate before failure. The MAC test was impractical because it required large, cumbersome equipment to generate the required magnetic fields. However, modern technologies have made this process easier. Now possible to carry out vacuum leak-rate testing in the field thanks to portable magnetrons and condition-based maintenance algorithms. The MAC test generates quantifiable data that can be incorporated into a predictive maintenance program. Because of this, technicians can monitor the health of vacuum interrupters over time, spot problems beforehand, and plan maintenance and/or replacement accordingly..

6. Continuous Liquid and Gas Monitoring (DGA)

Continuous monitoring of liquids and gases helps an operator to assess the health of power transformers by analyzing dissolved gases in their oil. Dissolved gas analysis (DGA) is a primary transformer health-monitoring tool used for preventive maintenance. The system regularly measures the amount of essential gases found in the petroleum:

- Hydrogen

- Methane

- Ethane

- Ethylene

- Acetylene

- Carbon Monoxide

- Carbon Dioxide

Abnormal levels of these gases can indicate potential issues, including:

- Overheating

- Arcing

- Partial Discharge

Acting early on gas-level deviations, DGA allows operators to recognize and fix the issue before failure. Timely electrical transformer fault detection enables rapid intervention and reduces the risk of unexpected downtime, thereby extending the life. Constantly monitoring dissolved gas analysis (DGA) is considered an essential tool for evaluating transformer health and is an important feature of predictive maintenance.

7. Bushing Monitoring

Online bushing monitoring systems can measure bushing condition in real time, regardless of weather, load, or voltage, with the same sensitivity as offline measurements. Typically, bushing tests are scheduled. Most often, we see them once every couple of years. However, in reality, many failure mechanisms in the bushings can initiate quickly. Sometimes, the failure mechanisms can occur within days or weeks. Also, some failures depend on temperature and voltage changes, and offline testing cannot reproduce this. Online bushing monitoring overcomes these shortcomings by continuously monitoring bushing performance in the field. Enhancing insight into transformers improves their performance and reliability and allows better prediction of failures and outages. With online monitoring, early signs of failure can be detected in time to avoid an expensive or disruptive failure.

8. Online Partial Discharge (PD)

The condition of electric insulating materials can be assessed using non-intrusive online partial discharge testing. This insensitive impedance measurement gives rise to significant potential issues, such as dielectric irregularities or weakness in the insulation, which can lead to a future breakdown. Online PD testing offers several key benefits:

- Continuous Monitoring of Cables: Tracks insulation health over time.

- Locating Problematic Joints and Terminations: Identifies weak points that may cause insulation breakdown.

- Prioritizing Cable Replacements: Helps decide which cables need replacement based on their condition.

- Ensuring Quality of Installed Cables: Verifies the integrity of cables after installation.

When electrical equipment is in service, system operators monitor partial discharge online, providing insight into insulation condition. Real-time data can help identify problems developing when something is operating normally. Once that is done, maintenance can be carried out to prevent unexpected failures.

9. Vibration Analysis

Vibration analysis of electrical motors is an analytical process that measures and analyzes vibration levels and frequencies to diagnose a motor’s health. Identifying issues that could affect a motor’s performance, life, or economy is essential. Vibration analysis is widely used in the aerospace, manufacturing, and automotive industries in a quite effective and reliable manner. Vibration analysis can be used for several purposes:

- Finding and Repairing Developing Problems: Identifies early signs of wear or damage before they become critical.

- Detecting and Monitoring Chronic Problems: Tracks recurring issues to manage long-term maintenance needs.

- Establishing Acceptance Criteria for Testing: Sets benchmarks for motor performance during acceptance testing.

- Predicting Failures: Forms part of a predictive maintenance strategy, allowing for proactive repairs.

A motor is equipped with an accelerometer to do vibration analysis. This device provides an electrical signal containing information about the motor’s vibration frequency and voltage, which helps diagnose faults.

10. Infrared Thermography (IR)

Infrared thermography is an effective technique for detecting potential problems in electrical systems. Infrared inspections, unlike conventional maintenance techniques, detect issues before signs of failure appear. You can intervene proactively. A primary benefit of infrared thermography is that it is a non-contact method. The scanning process enables a quick, efficient inspection of electrical equipment while in service. When using infrared thermography, there is no need for direct contact. Therefore, it causes minimal operational disruption. Also, it enables more comprehensive assessments with minimal downtime. During infrared inspections, it can identify common electrical problems:

- Loose Connections

- Overloaded Circuits

- Unbalanced Loads

- Faulty Equipment

A thermal image that doesn’t look quite right is a helpful indicator of a potential problem requiring further investigation, even if the issue isn’t immediately obvious. Infrared thermography helps in the smooth operation of any equipment or machinery. This allows the equipment to last longer and helps in avoiding costly breakdowns.

Conclusion

Innovative electrical testing methods have changed how people monitor their equipment and systems, enabling more precise, predictive evaluations. Insulation resistance profiling, sweep frequency response analysis, dielectric frequency response, and other techniques provide data on insulating condition, while sweep frequency response analysis, electromagnetic signature analysis, and other techniques assist in detecting faults in transformers, reactors, and other equipment. Real-time measurement is improved by continuous gas and liquid monitoring, bushing monitoring, partial discharge detection, and other online monitoring methods, which facilitate diagnosis and maintenance before failure. Vibration analysis and infrared thermography are two additional tools that help detect mechanical and thermal problems early, so that equipment life is longer and performance reliability improves.