The Electric Motor Nameplate: Decoding Ratings for Safe and Reliable Application

An electric motor is a fundamental component of modern industry, serving as the workhorse that converts electrical energy into mechanical energy through the principles of electromagnetism. These rotating machines are ubiquitous, found in applications ranging from simple residential appliances to complex industrial facilities. Given the wide variety of applications and electrical systems, standardized performance ratings and operating characteristics are paramount.

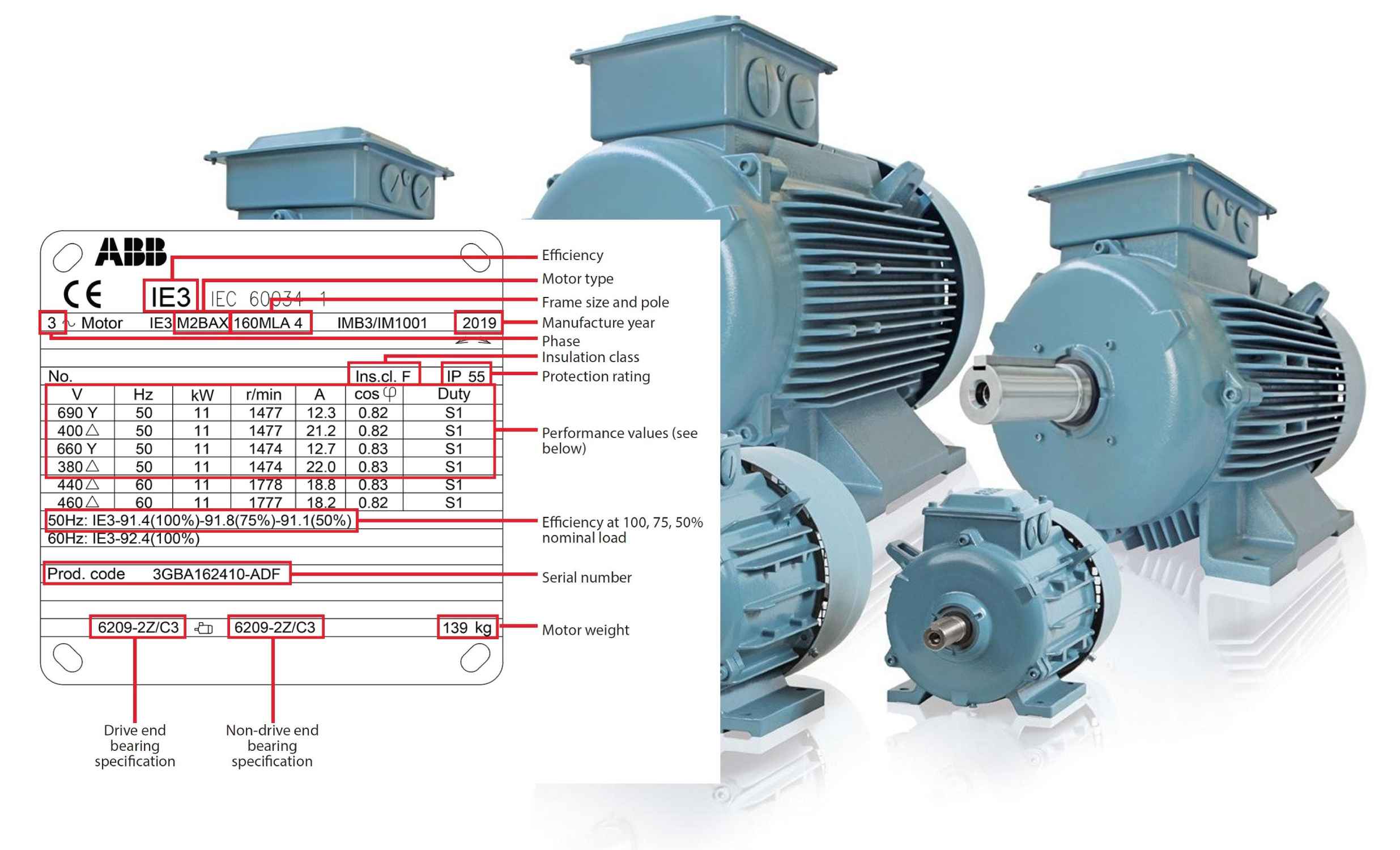

To ensure safe and reliable application, the National Electrical Manufacturers Association (NEMA) defines these ratings in NEMA Standard MG-1, which are coded on the motor nameplate at the time of manufacture. Furthermore, the National Electrical Code (NEC) specifies required markings for motor applications in NEC Section 430.7(A) to guide safe installation and operation. A comprehensive understanding of these nameplate ratings is essential for proper motor selection, installation, testing, and maintenance.

Key Nameplate Ratings Explained

The information presented on a motor nameplate can be categorized into identification, electrical, performance, and environmental/protection ratings.

I. Identification and Physical Characteristics

| Rating | Description |

| Manufacturer | Identifies the company that produced the motor, often including model or production numbers for tracking and documentation. |

| Frame Size | A standardized NEMA designation that indicates the motor’s physical dimensions, including critical mounting parameters such as foot hole pattern, shaft diameter, and shaft height. |

II. Electrical Ratings

These ratings define the electrical supply requirements and characteristics of the motor under normal operating conditions.

Voltage Rating

The voltage rating specifies the optimal operating voltage intended by the manufacturer. Motors are typically designed with a tolerance of pm 10% of the rated nameplate voltage. For instance, a 460V motor is expected to operate reliably over a range of 414V to 506V. Some motors are designed for dual-voltage operation, allowing the stator windings to be connected in series or parallel to accommodate different supply voltages. It is critical to note that most other nameplate ratings (e.g., power factor, efficiency, and current) are only valid when the motor is supplied with the rated voltage and frequency.

Rated Frequency and Number of Phases

The frequency indicates the number of times the AC sinusoidal voltage wave repeats per second, typically 60 Hz in North America and 50 Hz in many other parts of the world. The number of phases specifies the electrical supply configuration:

- Single-phase: Connected to one live conductor and a neutral.

- Three-phase (Polyphase): Connected to three live conductors, which is standard for most industrial motors.

Full-Load Current (FLA)

The Full-Load Current (FLA) is the maximum current drawn by the motor when operating at its rated horsepower and speed. This is a crucial rating used by electricians and engineers to correctly select:

- Wire size for the feeder circuit.

- Motor starter and control devices.

- Overload protection devices.

For multi-speed motors, the FLA is typically listed only for the maximum speed. The NEC requires this rating for proper circuit protection.

Code Letter (Locked-Rotor Amperes)

The Code Letter, ranging from A to V, indicates the motor’s locked-rotor kVA per horsepower (kVA/HP) at rotor stationarity (locked). This value is essential for sizing electrical system components, particularly overcurrent protection devices, as the starting (inrush) current can be many times the FLA.

III. Performance Ratings

These ratings quantify the motor’s mechanical output and operational characteristics.

Horsepower (HP)

Horsepower is the most common measure of a motor’s mechanical output rating. It represents the motor’s ability to deliver the required torque at the rated speed. The relationship between these values is defined by the formula:

HP = (Torque) x (Speed) / 5250. Torque is expressed in lb-ft, and Speed is expressed in RPM.

In the United States, one horsepower is equivalent to 746 watts of electrical power. The NEC mandates that the horsepower rating be listed on the nameplate for motors greater than 1/8 HP.

Speed and Slip

The speed characteristics of an AC induction motor are defined by three related values:

- Synchronous Speed (Ns): The theoretical speed of the rotating magnetic field inside the motor. It is determined by the supply frequency (f) and the number of magnetic poles (P) in the motor winding: Ns = (120 x f) / P

- Rated Full Load Speed (Nr): The actual speed of the motor shaft when operating at its rated load and horsepower. This speed is always slightly less than the synchronous speed due to friction and load.

- Slip (s): The difference between the synchronous speed and the actual full-load speed, typically expressed as a percentage. Slip is necessary to induce current in the rotor and generate torque. s = {(Ns – Nr) }x100 / Ns

For example, a four-pole motor operating at 60 Hz has a synchronous speed of 1,800 RPM. If its full-load speed is 1,750 RPM, the slip is approximately 2.78%.

Motor Efficiency (eta)

Efficiency is the ratio of mechanical output power to electrical input power, expressed as a percentage:

\eta = \frac{\text{Output Power}}{\text{Input Power}} \times 100

High efficiency is desirable, as the energy not converted to mechanical work is primarily lost as heat, which can degrade the motor’s insulation. Motor losses are typically categorized as Core, Stator, Rotor, Friction and Windage, and Stray Load losses.

Service Factor (SF)

The Service Factor is a multiplier that indicates the motor’s ability to operate above its rated horsepower for short periods without immediate damage. A motor with an SF of 1.15 can operate at 115% of its rated HP. For example, a 10 HP motor with a 1.15 SF can temporarily deliver 11.5 HP. However, continuous operation above the rated HP will generally reduce the motor’s expected lifespan.

Design Letter Code

NEMA assigns a Design Letter Code (A, B, C, or D) to classify the motor’s torque and current characteristics, guiding selection for specific load types.

| NEMA Design Code | Starting Torque | Starting Current | Slip | Typical Application |

| A | Normal | High | Low | General-purpose, high inrush current tolerance |

| B | Normal | Low | Low | Most common, general-purpose industrial loads |

| C | High | Low | Low | High starting torque loads (e.g., positive displacement pumps) |

| D | High | Low | High | High inertia loads requiring high slip (e.g., punch presses) |

Design Code B motors are the most widely used in industrial applications due to their versatility.

IV. Environmental and Protection Ratings

These ratings relate to the motor’s construction, thermal limits, and intended operating environment.

Insulation System Class and Temperature Ratings

The insulation system class (A, B, F, or H) defines the maximum allowable operating temperature of the motor windings. NEMA standards are based on a reference ambient temperature of 40 °C. The total maximum winding temperature is the sum of the ambient temperature, the allowable temperature rise, and a “hot spot” allowance.

| Insulation Class | Max Winding Temperature | Allowable Temp Rise (1.0 SF) |

| A | 105 °C | 60 °C |

| B | 130 °C | 80 °C |

| F | 155 °C | 105 °C |

| H | 180 °C | 125 °C |

For a Class F motor with a 1.0 Service Factor, the maximum operating temperature is calculated as 40 °C (Ambient) + 105 °C (Rise) = 145 °C. Classes F and H are common in modern industrial settings, especially when Variable Frequency Drives (VFDs) are used, which can introduce additional heating harmonics.

Time Rating

The time rating specifies how long a motor can operate at its rated load and ambient temperature.

- Continuous Duty: The standard rating, allowing for operation 24/7 without interruption (e.g., pump motors).

- Intermittent Duty: Rated for short durations (e.g., 5, 15, 30, or 60 minutes), often used for applications like valve actuators that operate periodically.

Enclosure Type (ENCL)

The enclosure type classifies the motor’s protection level against the operating environment and its cooling method. Common NEMA enclosure types include:

| Enclosure Type | Description | Typical Application |

| Open Drip Proof (ODP) | Protected against vertical dripping liquids; suitable for clean, dry, indoor environments. | General indoor use. |

| Totally Enclosed Fan Cooled (TEFC) | Protected against dirt and moisture, but not air-tight; uses an external fan for cooling. | Outdoor and dirty industrial locations. |

| Totally Enclosed Non-Ventilated (TENV) | Protected against dirt and moisture; relies on natural convection for cooling. | Damp or dirty locations without excessive heat. |

| Totally Enclosed Wash Down (TEWD) | Designed to withstand high-pressure water jets and high humidity. | Food processing or washdown areas. |

| Explosion-Proof (EXPL) | Designed to contain an internal explosion of specified gases or vapors without igniting the external atmosphere. | Hazardous (classified) locations. |

Thermally Protected (T.P.)

A motor marked “Thermally Protected” or “T.P.” is equipped with a thermal protector that interrupts power if the motor reaches an excessive temperature due to overload or failure to start. Power is reconnected once the motor has cooled to a safe temperature.

Heater Voltage

Motors in outdoor or high-humidity environments may be equipped with condensation prevention heaters. The nameplate will list the rated heater voltage and power (in watts). These heaters are energized when the motor is off to maintain the winding temperature above the dew point, preventing moisture accumulation. The NEC requires this marking to ensure a proper electrical supply is provided for the heater.

Conclusion

The motor nameplate is far more than a simple label; it is a concise technical summary of the motor’s design, capabilities, and limitations, codified by industry standards like NEMA MG-1 and the NEC. A thorough understanding of these ratings—from the fundamental electrical requirements (Voltage, FLA) to the critical performance metrics (HP, Slip, Efficiency) and environmental safeguards (Insulation Class, Enclosure Type)—is indispensable for ensuring the safe selection, installation, and long-term reliability of electric motors in any application.