Classification of Switches

Switches are essential components in electrical power systems. They are used to control, protect, and isolate electrical circuits during operation, maintenance, or fault conditions. Depending on their construction, operating conditions, and applications, switches are classified into different types. The most common types include Air-break switches, Isolators (Disconnecting switches), and Oil switches.

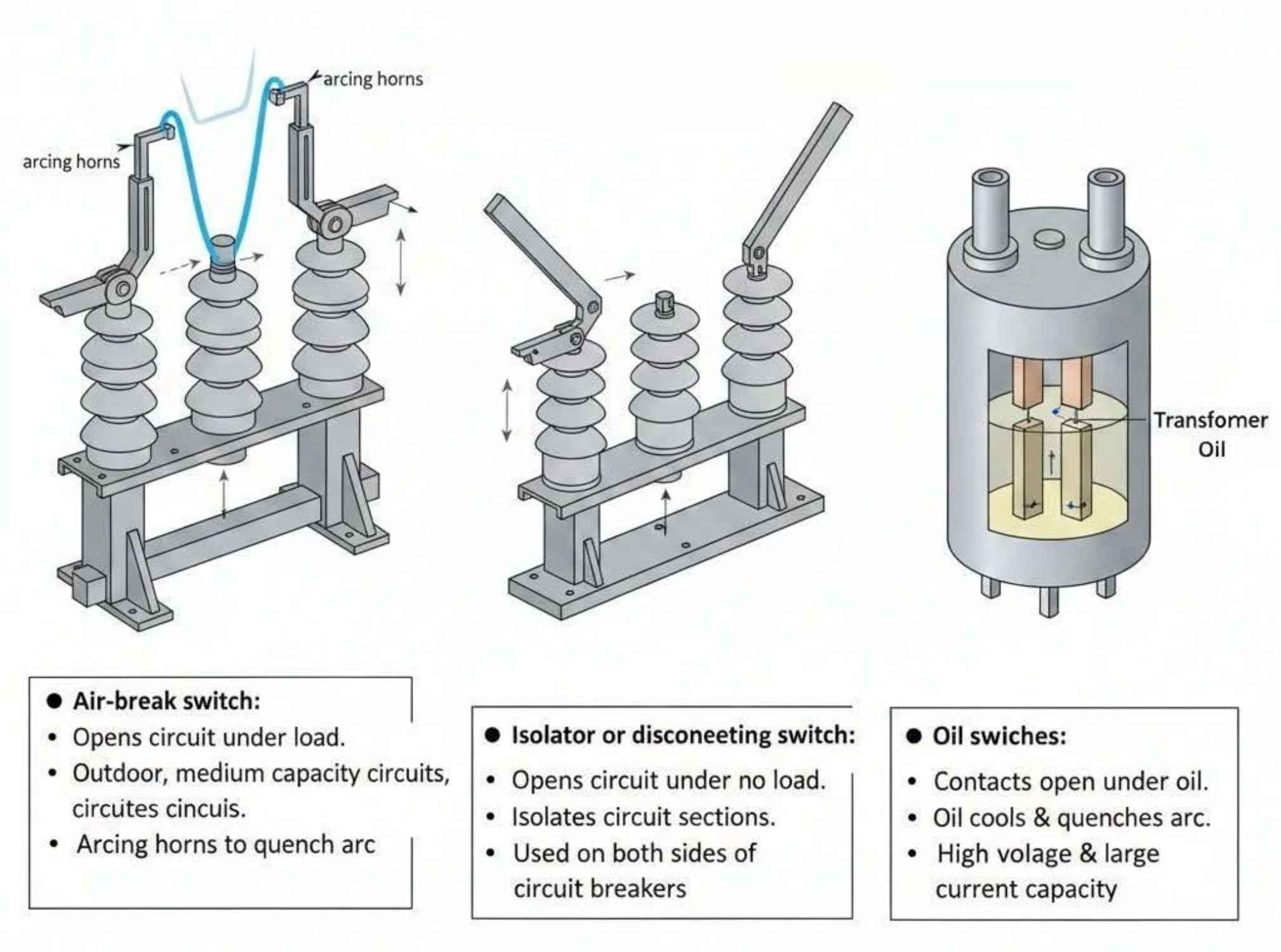

Air-Break Switch

An air-break switch is a type of switch that operates in air and opens a circuit under load. When the switch opens, an electric arc is produced between the contacts, which must be safely extinguished. These switches are mainly used outdoors for circuits of medium capacity, such as feeder lines supplying power to industrial loads from a main transmission line. To control and quench the arc formed during opening, arcing horns are provided.

Arcing horns are metal pieces attached to the switch contacts. During the opening operation, the arc forms between these horns rather than between the main contacts. As the switch opens further, the horns move farther apart, stretching and cooling the arc until it is finally extinguished. This design helps protect the main contacts from damage and extends the switch’s lifespan.

Isolator or Disconnecting Switch

An isolator, also known as a disconnecting switch, is designed to open a circuit only when there is no load. Its primary function is to isolate a section of the electrical system for maintenance or repair, ensuring personnel’s complete safety.

Isolators are not intended to interrupt current and should never be operated while current is flowing in the circuit. They are typically installed on both sides of circuit breakers, allowing the circuit breaker to be safely repaired or replaced without any risk of electric shock.

The correct operating sequence is very important:

- The isolator should not be opened until the circuit breaker is open.

- The isolator should always be closed before the circuit breaker is closed.

This sequence ensures that the isolator never carries or interrupts load current, maintaining system safety.

Oil Switches

In oil switches, the contacts are opened under oil, usually transformer oil. The oil serves two important purposes: it cools the arc and quenches it effectively when the circuit is opened. Oil switches are commonly used in circuits that involve high voltage and large current-carrying capacity, where air alone is insufficient to extinguish the arc safely. When the contacts separate, the arc’s heat vaporizes the surrounding oil, producing gas that helps deionize the arc path and rapidly interrupt the current.

Because of their effective arc-quenching capability, oil switches have been widely used in high-voltage power systems, although modern systems now often use more advanced technologies.

Conclusion

Each type of switch plays a specific role in power systems:

- Air-break switches handle load interruption in medium-capacity circuits.

- Isolators ensure safety by providing visible isolation under no-load conditions.

- Oil switches are suitable for high-voltage and high-current applications due to superior arc control.

Understanding the classification and function of switches is essential for the safe and efficient operation of electrical power systems.