Cable Management: Don’t Let Mess Cost You Efficiency

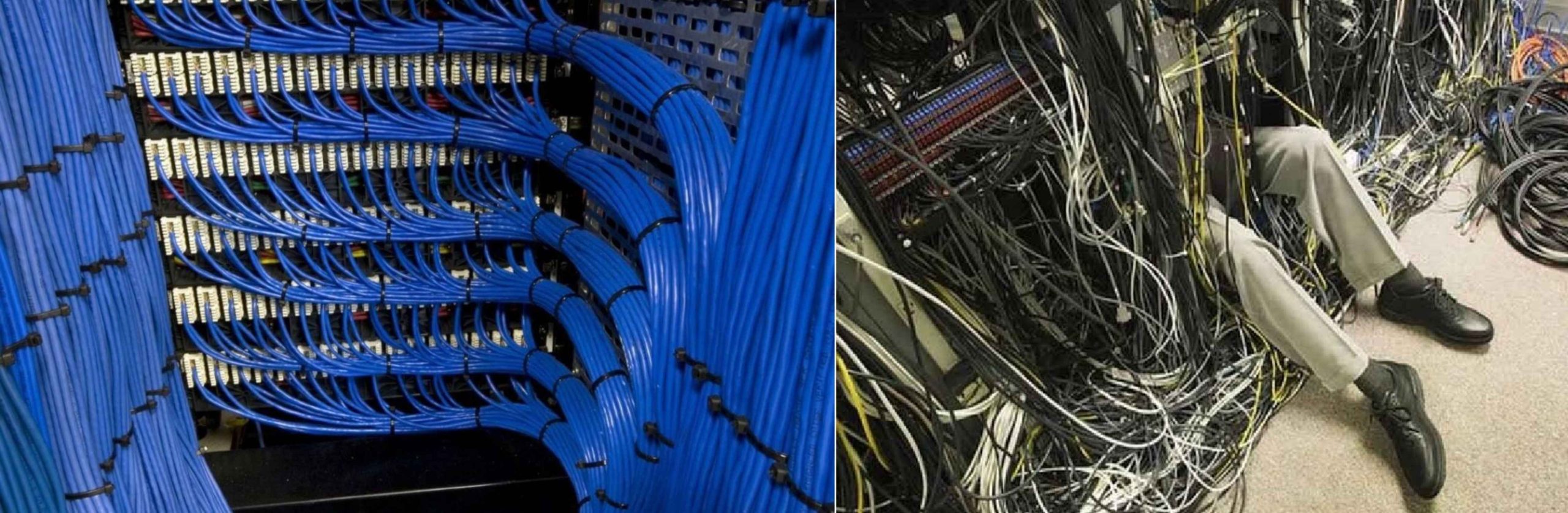

A tangled mess of cables isn’t just an eyesore — it’s a safety hazard, a potential reliability killer, and a productivity nightmare.

For anyone working in engineering, tech, or operations, cable management should be treated as critical infrastructure, not a task to tackle when there’s time left over. Proper cable management isn’t just about neatness; it’s about building a system that’s safe, efficient, and scalable. Here’s why you should care and how to make sure you’re on the right track.

⚡ Top Cable Management Tips & Common Pitfalls to Avoid

1. Plan Before You Pull

Quick fix: Random cable runs or last-minute adjustments lead to a tangled mess.

Why it matters: Careful planning minimizes future maintenance headaches, improves troubleshooting efficiency, and helps avoid hidden faults that could impact your system’s reliability.

2. Respect Tray and Conduit Limits

Quick fix: Overloading trays or conduits might seem like a time-saver.

Why it matters: Cramming too many cables into a small space leads to heat buildup, insulation failure, and even fire hazards. Always leave room for airflow to maintain safety and longevity.

3. Label Everything

Quick fix: Labeling cables may seem tedious, but the payoff is enormous.

Why it matters: Unlabeled cables can waste hours during troubleshooting, commissioning, or audits. A clear label system ensures that any technician can quickly identify each cable’s purpose.

4. Separate Power and Data Cables

Quick fix: Running power and data cables together might save a few minutes of installation time, but it’s not worth the risk.

Why it matters: Mixing power and data can lead to electromagnetic interference (EMI), signal loss, and unwanted shutdowns. Keep them separate to reduce the risk of issues down the road.

5. Avoid Sharp Bends and Twists

Quick fix: Bending cables sharply or twisting them around tight corners may seem like a way to save space.

Why it matters: This creates stress points that can damage cables, shorten their lifespan, and increase electrical resistance, causing potential failures. Always keep bends gradual and cables properly routed.

6. Secure Loose Cables

Quick fix: Letting cables dangle may seem harmless, but it creates unnecessary wear.

Why it matters: Loose cables are prone to damage, collecting dust, or even causing short circuits if they’re pulled or get in the way of machinery. Secure all wires in place with the proper ties and clips.

7. Inspect Periodically

Quick fix: Once cables are installed, it’s easy to forget about them.

Why it matters: Even the best cable setups degrade over time. Environmental factors like heat, vibration, or corrosion can quietly damage your system. Regular inspections help catch minor issues before they become bigger problems.

8. Don’t Overlook Aesthetics

Quick fix: A clean, neat installation might seem like a cosmetic concern.

Why it matters: Organized cables reflect professionalism and make upgrades, audits, and team coordination far easier. Plus, it’s much easier to troubleshoot a clean system than one in chaos.

9. Use Quality Support Systems

Quick fix: Cheap trays, ties, and clamps might save money upfront, but they can cost you more in the long run.

Why it matters: Quality materials hold up over time, keeping cables secure and functioning. Cheap alternatives may break down quickly, leading to future downtime and more maintenance costs.

10. Document Everything

Quick fix: Relying on memory or hoping you’ll “figure it out later” is never a good idea.

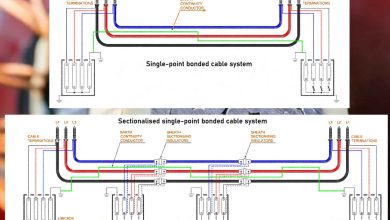

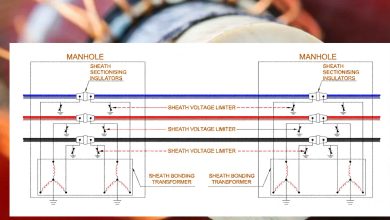

Why it matters: A clear diagram or routing record saves countless hours during system troubleshooting, upgrades, or modifications. The time you invest in documentation now will pay off later when things need to be fixed or changed.

Why Cable Management Matters

At the end of the day, good cable management isn’t just about keeping things neat — it’s about preventing downtime, improving safety, and saving money. A well-managed system is more efficient, more reliable, and much easier to maintain. Think of cable management as a discipline that separates proactive engineers from reactive technicians. In the fast-paced world of tech and engineering, being prepared means having the right systems in place — from the first cable pulled to the last one tied down.