An electrical substation serves as a crucial junction point where multiple transmission lines converge. In practice, many Extra High Voltage (EHV) and High Voltage (HV) substations can have more than six lines terminating there. In substantial transmission substations, this number can exceed two dozen. The bus scheme of a substation refers to the layout of overhead bus bars and associated switching equipment, including circuit breakers and isolators. The design of the bus scheme significantly affects the substation’s operational flexibility and reliability.

One of the primary goals of substation design is to prevent a total shutdown caused by maintenance activities or faults on connected lines. If a substation is completely shut down, all lines connected to it will also be deactivated. Therefore, EHV or Ultra High Voltage (UHV) substations, which handle numerous vital lines, must be engineered to minimize total failures and limit the number of interrupted circuits. There are six prevalent substation bus configurations that every technician should familiarize themselves with:

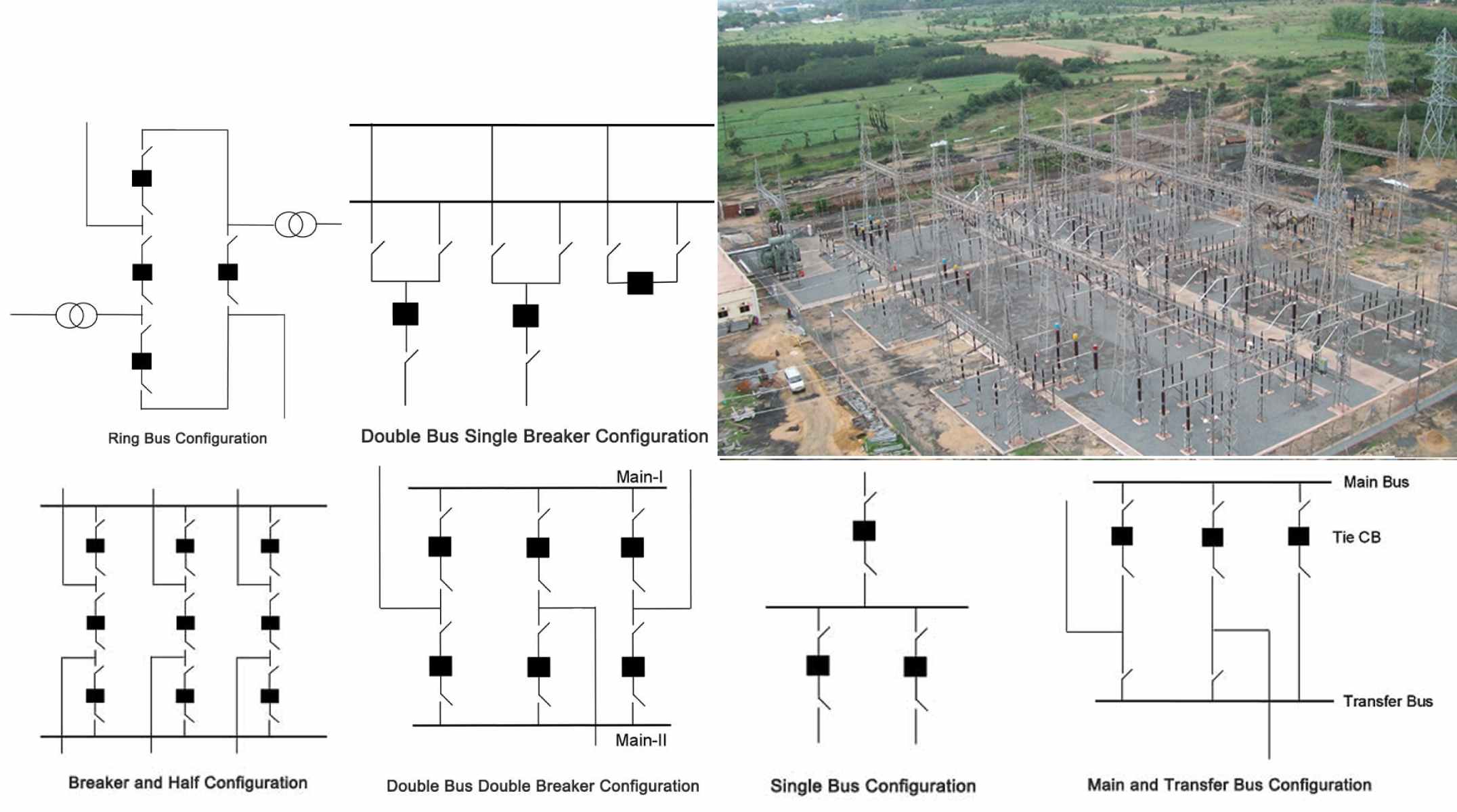

- Single Bus Configuration: As the name suggests, this configuration connects all circuits to a single main bus. If a fault occurs on the bus or between the bus and the circuit breaker, the whole substation can experience an outage. Maintenance on circuit breakers necessitates shutting down the corresponding line, while bus maintenance requires a complete bus shutdown. To manage this, a bypass switch should be installed across the circuit breaker during maintenance, disabling circuit protection. This configuration is the simplest and least costly, requiring less space and allowing for easy expansion. However, it’s not considered reliable and is typically used in substations that don’t demand high reliability, such as large transmission yards. Reliability can be enhanced by adding complex bus arrangements.

- Main Bus and Transfer Bus Configuration: This setup builds on the single-bus scheme by introducing one or more additional buses. Circuit breakers may be employed to link the main and transfer buses. Without a Tie Circuit Breaker (CB), the transfer bus can be energized by closing the isolators, allowing for maintenance on a circuit breaker by isolating it on both sides. When a tie CB is involved, maintenance can be done by energizing the transfer bus through the tie breaker. While more reliable and expandable than a single-bus configuration, the main and transfer bus design is more intricate and costly, with complex switching procedures that can cause outages if a breaker fails.

- Double Bus Double Breaker Configuration: In this design, there are two buses and two breakers for each circuit. Both buses are generally energized, enabling any circuit to undergo maintenance without interrupting the circuit’s operation. If one bus fails, the circuits can still be powered through the functioning bus. Although this configuration requires twice the equipment as a single-bus configuration, its high reliability makes it suitable for EHV transmission substations or generating stations, enabling effective load balancing.

- Double Bus Single Breaker Configuration: This configuration features two buses where each circuit is connected to both buses through a single breaker. A tie breaker connects the two main buses and is typically kept closed, offering more operational flexibility. However, a fault on one bus demands its isolation, affecting the connected circuits.

- Ring Bus In a ring bus configuration, circuit breakers are connected to form a continuous loop, with isolators located on both sides of each breaker. Circuits connect the breakers, allowing each to be powered from either direction. This setup offers excellent operational flexibility and high reliability, as any circuit breaker can be switched off for maintenance without disrupting service to other circuits. In the event of a fault, the affected circuit can be isolated by tripping the breakers on either side, ensuring that only the faulty section is taken offline. In contrast, the remaining circuits continue to operate. However, a significant drawback of the ring bus system is that a fault can split the ring into two isolated sections. These sections may lack the necessary combination of source and load circuits, though this issue can be mitigated by arranging the circuits in proximity. The ring bus can be expanded to include additional circuits, although it is generally not suited for more than six. Careful planning is essential to avoid complications during future expansions.

- Breaker-and-Half Substation Configuration: When a substation needs to accommodate more circuits, the ring bus scheme can evolve into a breaker-and-half configuration. This setup uses two main buses, which are typically both energized, with three breakers connecting them. This configuration requires three breakers for every two circuits, hence the term “one and a half breaker.” It can be visualized as needing one complete breaker and an additional half to control a single circuit. The middle breaker serves both circuits, as in a ring bus setup, where each circuit is supplied from both sides. In this arrangement, any circuit breaker can be taken offline for maintenance without affecting the service to any remaining circuits.

Additionally, one of the main buses can be isolated for upkeep while still providing uninterrupted service to the other circuits. In the case of a failure in a middle circuit breaker, the adjacent breakers will trip to disconnect both circuits involved. Conversely, if a breaker near the bus fails, tripping the middle breaker will not disrupt service to the adjacent circuit; it will only affect the circuit associated with the failed breaker. The breaker-and-half design is highly flexible and reliable, offering a more cost-effective solution than a double-bus, double-breaker scheme. However, the protective relay setup in this configuration can be quite complex, as the middle breaker interacts with two circuits and requires more physical space to accommodate a larger number of components. These configurations are essential knowledge for technicians working within substations to ensure optimal performance and reliability in electrical transmission systems.