Sweep Frequency Response Analysis (SFRA) Insights: A Comprehensive Review of Frequency Range Sensitivities

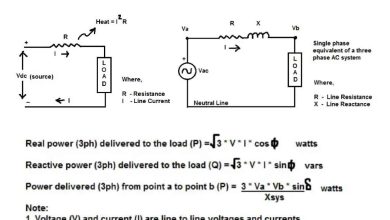

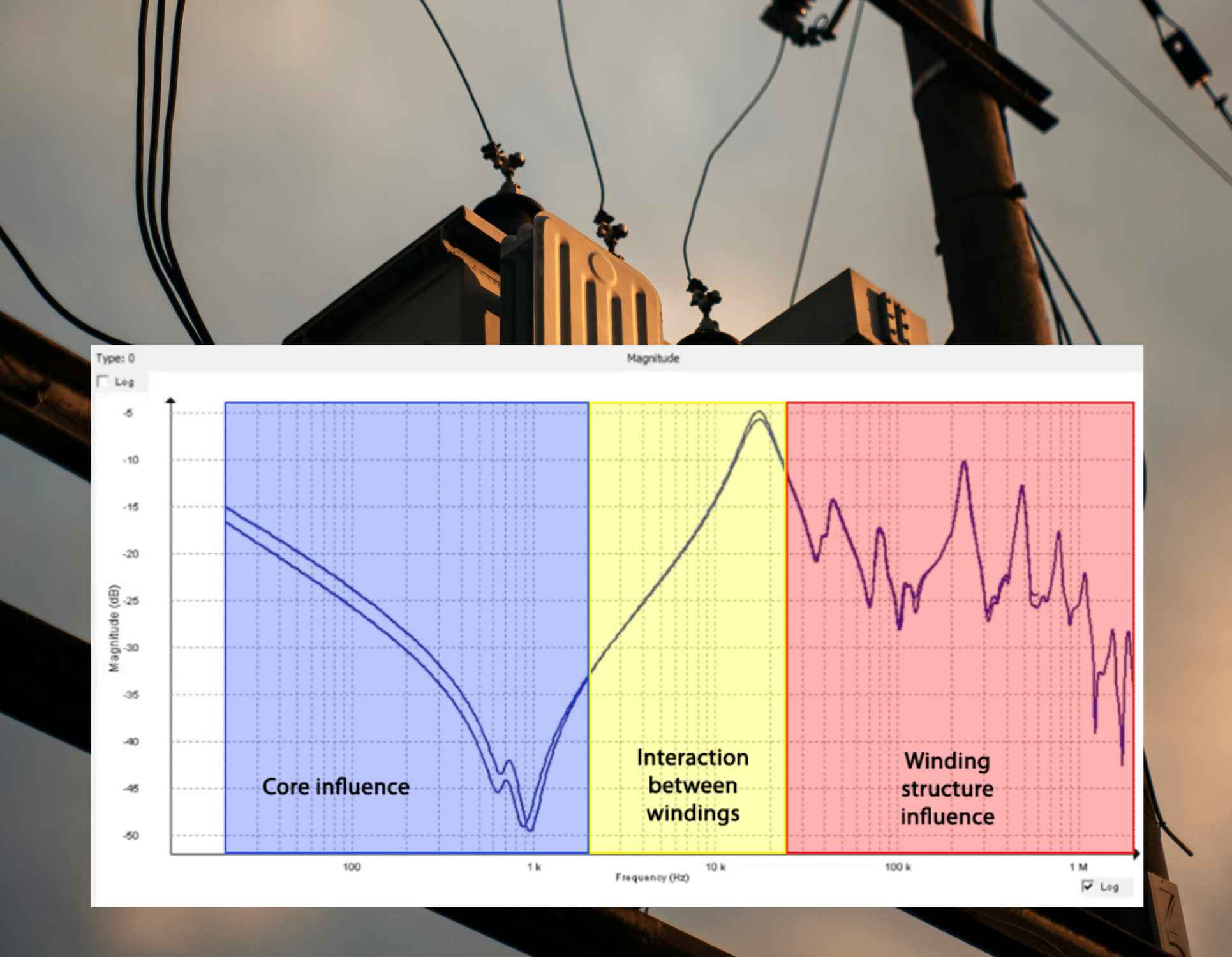

Sweep Frequency Response Analysis (SFRA) is an established and critical diagnostic technique employed to evaluate the mechanical and electrical integrity of power transformers. The method involves injecting a low-voltage sinusoidal signal spanning a broad frequency range into the transformer windings and measuring the resulting transfer function. By analyzing the magnitude and phase responses, SFRA can effectively detect subtle anomalies such as winding displacements, core movements, and insulation issues, which are often precursors to catastrophic failure. The frequency response is systematically segmented into distinct ranges—low, mid, and high—each corresponding to the physical characteristics and potential defects within the transformer structure.

Frequency Range Sensitivities in SFRA

The diagnostic power of SFRA lies in the principle that different frequency ranges are sensitive to distinct physical components and failure modes within the transformer. A clear understanding of these sensitivities is paramount for accurate fault localization.

| Frequency Range | Typical Range | Primary Sensitivity | Associated Physical Components/Issues |

| Low Frequency | Up to a few kHz | Core and Major Winding Structure | Core movement, loose core laminations, shortened turns, major winding deformation |

| Mid Frequency | Tens of kHz | Winding-to-Winding Interactions | Radial and axial winding displacements, changes in inter-winding coupling |

| High Frequency | Hundreds of kHz to MHz | Fine Winding Structure and Insulation | Turn-to-turn faults, insulation degradation, and conductor spacing issues |

| Ultra-High Frequency | >1 MHz | Parasitic Elements and Test Setup | Test lead length, shielding, grounding, parasitic capacitance/inductance |

Low Frequency Range (Up to a Few Kilohertz)

The low-frequency response is predominantly governed by the transformer’s core and the overall geometry of the major windings. Anomalies in this range, typically extending up to a few kilohertz (kHz), are highly indicative of large-scale mechanical failures. Specifically, issues such as core movement, loose core laminations, or significant winding deformation (e.g., radial buckling or axial collapse) will alter the low-frequency response. Furthermore, the detection of shorted turns is often most reliable within this range, as these faults significantly change the overall winding inductance.

Mid Frequency Range (Tens of Kilohertz)

The mid-frequency range, generally spanning tens of kilohertz, is primarily sensitive to the interactions and coupling between the transformer windings. Mechanical displacements or changes in the magnetic coupling between the primary and secondary windings are the principal factors influencing the response in this region. This range is particularly valuable for identifying winding interaction issues, as its response is less influenced by core anomalies or the fine structural details of the windings. A change in the mid-frequency signature strongly suggests a winding displacement or a mechanical coupling problem.

High Frequency Range (Hundreds of Kilohertz to Megahertz)

The high-frequency response, extending from hundreds of kilohertz to the megahertz (MHz) range, is sensitive to the fine structure of the windings. This includes the detailed turn-to-turn arrangement, the integrity of the inter-turn and inter-coil insulation, and the precise conductor spacing. Variations in this range are critical indicators of detailed structural or insulation defects that may be invisible at lower frequencies.

Ultra-High Frequency Range (Above 1 Megahertz)

In the ultra-high frequency range (above 1 MHz), the SFRA measurement is increasingly dominated by parasitic capacitances and inductances, both within the transformer and in the external test setup. At these elevated frequencies, the measurement environment—including the length of the test leads, the shielding quality, and the grounding scheme—can significantly influence the measured response. While true winding or insulation defects may still manifest, careful interpretation is required to distinguish genuine anomalies from measurement artifacts caused by external influences. This range is therefore useful for identifying subtle winding or insulation issues, but only when interpreted alongside controlled and consistent test conditions.

Summary of Diagnostic Indications

- Low-Frequency Range: Peaks, dips, or shifts in the response indicate potential core or major winding issues.

- Mid-Frequency Range: Changes in the response suggest mechanical coupling problems or winding displacement.

- High-Frequency Range: Variations in the response point to detailed structural or insulation issues within the windings.