Comprehensive TTR Troubleshooting Guide: Hand-Crank Preliminary Checks

Introduction

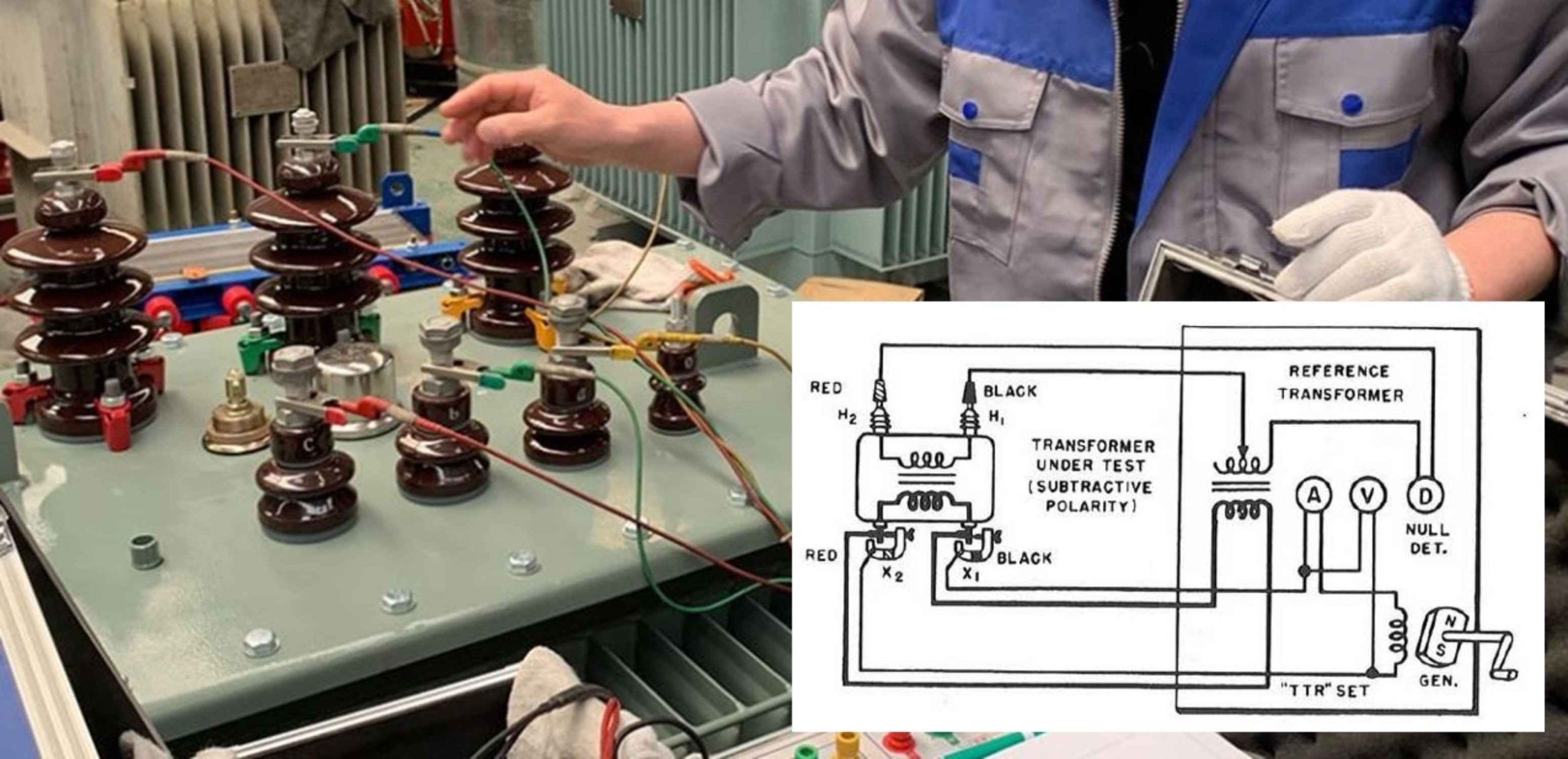

The Transformer Turns Ratio (TTR) test set is a critical instrument for assessing the health and integrity of power and distribution transformers. While modern TTR instruments are electronic, many field technicians still rely on older, highly robust hand-crank TTR sets. These vintage instruments, such as the Biddle Model 3-TTR, are susceptible to mechanical wear and electrical component degradation, which can lead to inaccurate readings or inoperative states.

To ensure the continued reliability and accuracy of a hand-crank TTR set, a series of preliminary checks must be performed regularly. These checks systematically isolate and verify the function of the core components: the hand-crank generator, the metering circuits, and the measuring bridge. The following guide expands on the standard checks with additional technical detail and diagnostic information, primarily referencing the operational principles of classic single-phase hand-crank TTR designs.

1. The Null Check (Generator and Metering Verification)

The Null Check is the foundational test, designed to confirm the operational integrity of the instrument’s internal power source and its associated metering.

Objective

To verify the functionality of the hand-crank generator, the voltmeter, the ammeter, and the continuity of the primary excitation circuit.

Procedure

- Zeroing: Adjust all ratio measurement dials to their zero position (0.000).

- Clamping: Close both the X1 and X2 excitation clamps firmly onto their respective anvils to complete the internal primary circuit.

- Isolation: Electrically separate the X1 and X2 clamps, and ensure the H1 and H2 secondary clips are electrically isolated from each other and ground.

- Cranking and Observation: Crank the generator to produce a stable 8 Volts as indicated on the internal voltmeter. Simultaneously observe the ammeter and the required cranking speed.

Expected Outcome and Technical Analysis

When the generator is properly magnetized and operating under a normal, unloaded internal burden, the following should be observed:

- Voltage: A stable 8V reading on the voltmeter.

- Current: The ammeter pointer should deflect approximately 3 divisions on the ÷5 range and 1/2 division on the X1 range. This reading confirms the excitation current required to power the internal reference transformer and metering circuits.

- Speed: The 8V output should be achieved at a cranking speed of approximately 120 Revolutions Per Minute (RPM).

Troubleshooting and Diagnosis

| Symptom | Probable Cause | Corrective Action |

| Voltmeter reads 0V (or fails to deflect) | Faulty generator, defective voltmeter, or a complete wiring defect (open circuit). | Use a separate volt-ohmmeter to check generator output and circuit continuity, referencing the test set’s wiring diagram. |

| Ammeter indicates high current (or generator is hard to crank) | Short circuit in the generator output circuit, potentially in the wiring leading up to the X1 and X2 clamps. | Isolate components (generator, wiring, clamps) and use an ohmmeter to locate the short. |

| Excessive cranking speed (> 120 RPM) required for 8V | Demagnetization of the generator’s permanent magnets or an abnormal burden (e.g., partial short) on the generator. | Consult the test set manual for re-magnetization procedures; check for partial shorts or excessive friction in the mechanical drive. |

2. The Zero Ratio Check (Reference Transformer and Dial Verification)

The Zero Ratio Check verifies the accuracy of the instrument’s internal reference components when the ratio is set to zero.

Objective

To confirm the proper function and balance of the reference transformer and the null detector circuit at a theoretical zero ratio setting.

Procedure

- Connection: Close the X1 and X2 clamps on their anvils. Electrically connect the two secondary leads, H1 and H2, together (short-circuited).

- Setting: Ensure all ratio dials are set to zero (0.000).

- Cranking and Nulling: Crank the generator to maintain 8V. Observe the galvanometer (null detector).

- Adjustment: If the galvanometer does not read zero (null), adjust the fourth dial until the meter reads zero while cranking at 8V.

Expected Outcome and Technical Analysis

The fourth dial should read zero within half a division of its zero mark. Any error in this check directly affects the accuracy of the fourth-dial reading by the magnitude of the observed error.

Note: This check is often performed with the transformer under test connected to the exciting leads, as a short-circuit on the secondary leads effectively simulates a zero-ratio condition in the test set’s bridge circuit.

Troubleshooting and Diagnosis

•Failure to Obtain Null: If a balance cannot be achieved, the trouble is likely in the reference transformer or the fourth dial mechanism.

•No Signal/Deflection: If the galvanometer shows no deflection at all, the issue may lie in the synchronous rectifier, the detector (galvanometer) itself, or the internal wiring.

3. The Unity Ratio Check (Bridge and Synchronous Rectifier Verification)

The Unity Ratio Check is the final preliminary test that confirms the overall accuracy of the measuring bridge at a known 1:1 ratio.

Objective

To verify the overall accuracy and balance of the measuring bridge, with a specific focus on the condition and balance of the synchronous rectifier.

Procedure

- Connection: Close the X1 and X2 clamps on their anvils. Connect the black secondary lead H1 to the black exciting lead X1. Connect the red secondary lead H2 to the red exciting lead X2. This creates a direct 1:1 ratio connection.

- Setting: Set the ratio dials to read 1.000.

- Cranking and Nulling: Crank the generator to maintain 8V. Observe the galvanometer.

- Verification: The set should read within half a division of zero on the fourth dial.

Expected Outcome and Technical Analysis

The galvanometer should achieve a null (zero reading) when the dials are set to 1.000. This confirms that the internal bridge circuit is balanced and that the synchronous rectifier is functioning correctly to convert the AC null signal to a DC signal for the galvanometer.

Crucial Note: This check must be made with no connections to the leads other than the specified H1-X1 and H2-X2 connections.

Troubleshooting and Diagnosis

- Null Detector Reading Out of Tolerance: If the null reading is outside the specified tolerance, the synchronous rectifier is the most likely cause. It may be out of balance or defective.

- Action: Consult the test set manual for the specific procedure required to accurately balance the synchronous rectifier. If balancing fails, the component may need to be replaced.

- Inconsistent Failure: If a null is obtained in the Unity Check but not the Zero Ratio Check, the issue is more strongly indicated to be in the reference transformer or the fourth dial. Conversely, if the Zero Ratio Check passes but the Unity Check fails, the synchronous rectifier is the primary suspect.

Summary of Component-Specific Diagnostics

For more advanced troubleshooting, a technician may need to check the resistance and current values of key internal components.

| Component | Key Diagnostic Parameter | Normal Condition (Example: Biddle Model 3-TTR) | Symptom of Failure |

| Generator | Output Voltage/Speed | 8 Volts at 120 RPM (unloaded) | Requires excessive speed for 8V (demagnetization) or hard cranking (short circuit). |

| Reference Transformer | Magnetizing Current | Approximately 70 milliamperes (mA) at 8 Volts. | Magnetizing current in excess of 100 mA indicates a problem with the core or windings. |

| Detector (Galvanometer) | Sensitivity/Resistance | 200-0-200 microamperes sensitivity; 150 ohms resistance. | No deflection or erratic movement; can be checked with a small battery and resistor. |

| Synchronous Rectifier | Balance/Resistance | Requires specific balancing procedure; resistance between terminals can be measured. | Failure to null in Unity Check; requires factory repair or specialized balancing. |