Secondary Current Injection (SCI) Testing: A Detailed Explanation

1. Definition and Core Principle

Secondary Current Injection (SCI) testing is a fundamental and widely used procedure in the commissioning and maintenance of electrical power system protective relays. It is defined as the process of injecting a precisely controlled, low-level alternating current (AC) or direct current (DC) signal directly into the secondary terminals of a protective relay. This process effectively simulates a fault condition on the primary power system without requiring high currents to be applied to the main circuit or the primary windings of the current transformers (CTs).

The core principle is to verify the functional integrity of the relay’s internal logic and timing characteristics. The injected secondary current is scaled to be proportional to the expected primary fault current, based on the CT ratio, allowing the relay to “see” a simulated fault and respond as designed.

2. Key Purposes and Objectives

The primary objective of SCI testing is to ensure that the protective relay operates accurately, reliably, and selectively in accordance with its specified settings and the overall protection scheme. The key purposes include:

| Purpose | Detailed Explanation |

|---|---|

| System Safety and Isolation | By working exclusively on the secondary side (typically 1A or 5A circuits), the test avoids the inherent dangers and logistical complexities of applying high currents to the primary system, ensuring greater safety for personnel and equipment. |

| Accuracy and Speed Verification | The test allows for precise control over the magnitude and phase angle of the injected current. This enables accurate measurement of two critical parameters: the pickup value (the current at which the relay initiates operation) and the operating time (the time delay until the trip contact closes). |

| Sensitivity Confirmation | It confirms that the relay’s programmed current threshold, or pickup setting, is correct. This ensures the relay is sensitive enough to detect minimum fault currents but stable enough to ignore normal load currents. |

| Coordination and Selectivity | This is crucial for verifying the time-current characteristics of multiple relays connected in series. The test ensures that the protection scheme maintains selectivity, meaning the relay closest to the fault operates first, isolating only the faulted section and minimizing the impact on the rest of the system. |

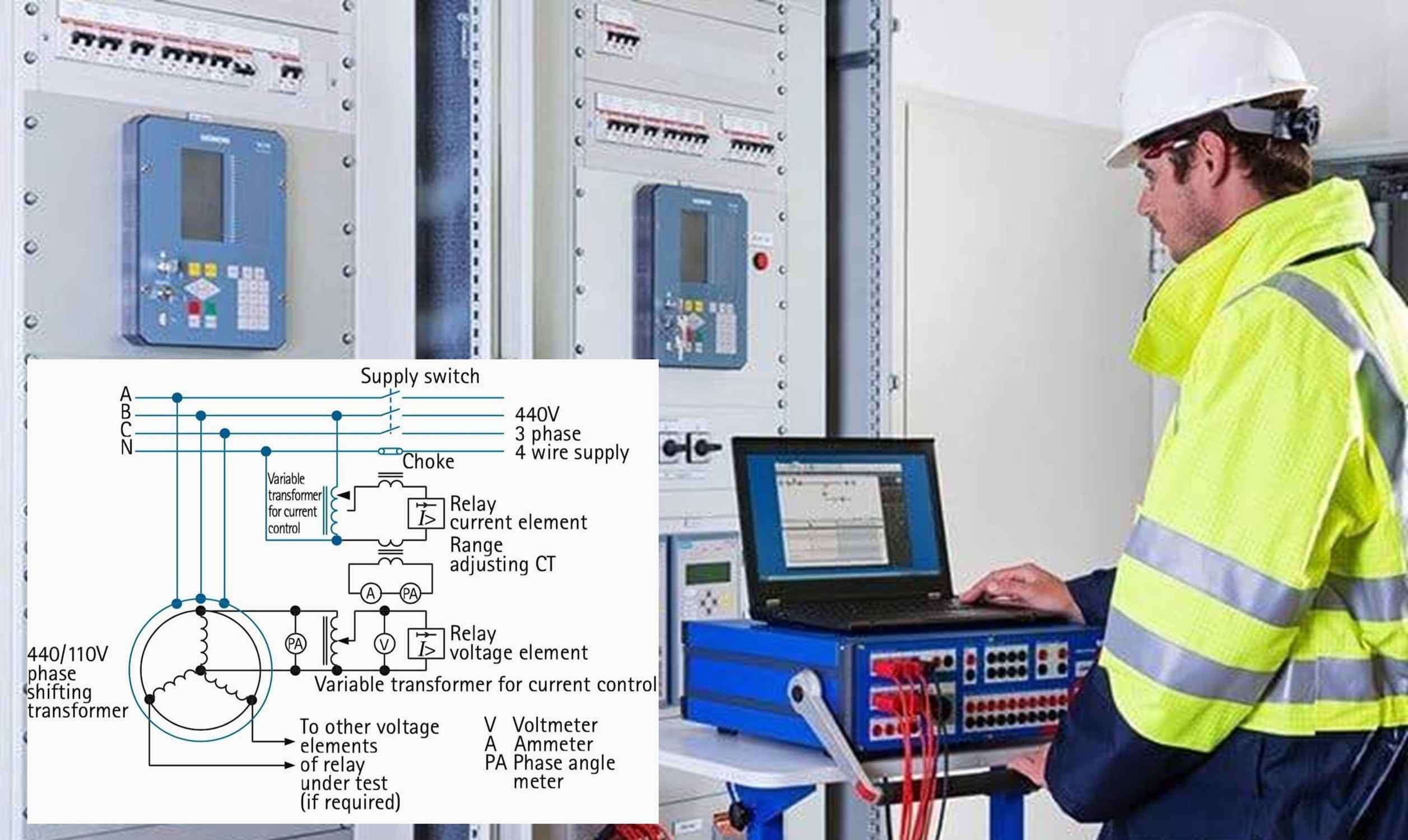

3. Procedure for Secondary Current Injection Testing

The testing process is systematic and requires specialized equipment, typically a dedicated Secondary Injection Test Set. The general steps are as follows:

- Isolation and Safety Precautions: The protective relay must be electrically isolated from the primary circuit, or its trip outputs must be secured (e.g., by placing the circuit breaker control switch in the “Trip Blocked” or “Non-Auto” position) to prevent an inadvertent trip of the main circuit breaker during the test.

- Test Equipment Connection: The output of the secondary injection test set is connected directly to the current input terminals of the protective relay (e.g., the terminals that would normally receive the CT secondary current).

- Setting the Test Parameters: The test current values are calculated based on the relay’s programmed settings. For example, to verify an overcurrent relay with a pickup setting of 5A, the technician might inject currents at 50%, 100%, 120%, and 200% of the pickup value.

- Injection and Observation: The test set injects the calculated current. The technician observes the relay’s response, specifically:

- The activation of the pickup indicator (LED).

- The time taken for the relay’s trip contact to close, which is measured by the test set’s internal timer.

- Data Recording and Comparison: The measured pickup current and operating time are recorded. These results are then rigorously compared against the relay’s specified characteristics, the manufacturer’s data, and the system’s protection philosophy. Any deviation outside the acceptable tolerance range necessitates a relay setting adjustment or repair.

4. Advantages of Secondary Current Injection

SCI testing is the preferred method for functional verification due to several key advantages:

- Safety: It is inherently safe as it operates at low energy levels, eliminating the risk associated with high-voltage or high-current primary injection.

- Efficiency and Economy: It is a relatively quick, cost-effective, and easy-to-apply test that does not require a system outage or the use of heavy, high-current primary injection equipment.

- Precision and Controllability: The test set provides highly precise control over the injected current magnitude and duration, allowing for detailed and repeatable verification of the relay’s characteristic curve.

- Versatility: It is applicable to virtually all types of protective relays, including:

- Overcurrent Relays (50/51)

- Earth Fault Relays (50N/51N)

- Differential Relays (87)

- Directional Relays (67)

5. Best Practice Recommendation

A critical best practice, especially when testing complex relays like Differential Relays (87), is to follow the correct sequence and phase relationship of the injected currents. For differential protection, the test must simulate the current flow for both internal and external faults to verify the relay’s stability and operation zones accurately.

Always ensure that the test results are meticulously documented and compared against the standard specifications (e.g., ANSI, IEC) to guarantee the protective system will perform its critical function when a real fault occurs.