Transformer Insulating Fluid Sampling Protocol: The Critical Role of Specific Gravity

One of the most vital components of a comprehensive transformer maintenance program is the periodic testing of its insulating fluid. The accuracy of this testing, however, is fundamentally dependent on obtaining a representative fluid sample, which requires a precise understanding of the fluid’s specific gravity (SG). The specific gravity dictates the fluid’s behavior, particularly its interaction with free water, and thus determines the optimal location for sample extraction.

Understanding Specific Gravity and Water Migration

Specific gravity is a dimensionless quantity defined as the ratio of the density of the insulating fluid to the density of water at a specified temperature. Mathematically, this relationship is expressed as:

SG = Density of Sample / Density of Water

Since water has a specific gravity of 1.0, the insulating fluid’s SG is the primary factor governing the migration of free water within the transformer tank. This is a critical consideration because the dielectric breakdown strength of most insulating fluids is inversely related to their water content; an increase in water content directly correlates with a reduction in the fluid’s dielectric strength.

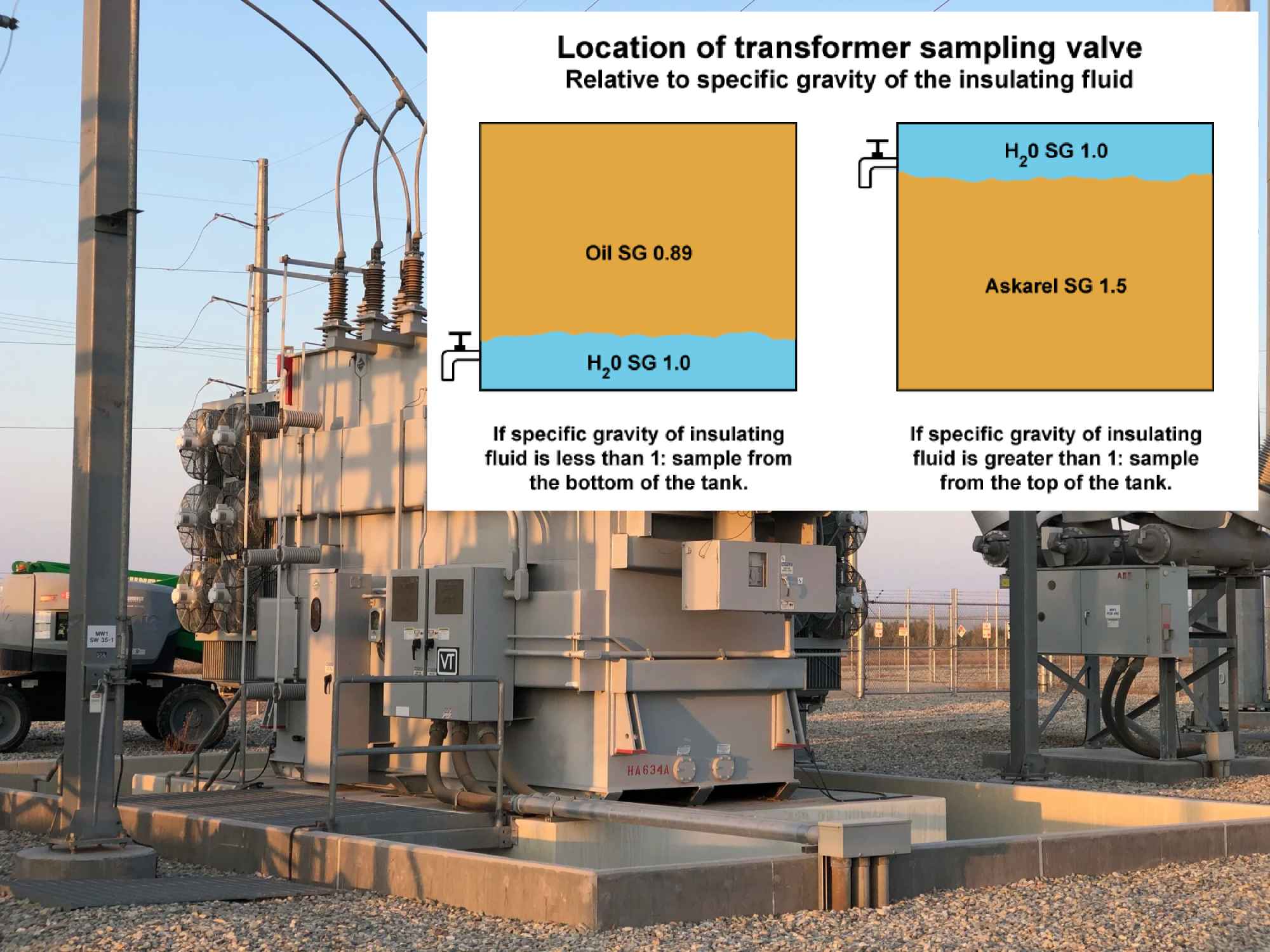

The physical principle of buoyancy dictates the location of free water:

- If the insulating fluid’s SG is greater than 1.0, the fluid is denser than water, causing any free water to migrate and settle at the top of the fluid column.

- If the insulating fluid’s SG is less than 1.0, the fluid is less dense than water, causing the free water to migrate and settle at the bottom of the fluid column.

For example, mineral oil, with an SG of approximately 0.89, is less dense than water (SG 1.0) and will float on top of it. In this scenario, sampling from the bottom of the tank is necessary to capture the highest concentration of free water, which is essential for an accurate assessment of the fluid’s condition.

Establishing the Sampling Location Rule of Thumb

To ensure the sample collected is representative of the fluid’s condition, particularly its water contamination level, a clear protocol based on specific gravity must be followed.

| Condition | Specific Gravity (SG) | Sample Location | Rationale |

| Denser than Water | SG > 1.0 | Top of the Tank | Free water, being less dense, floats to the top. |

| Lighter than Water | SG < 1.0 | Bottom of the Tank | Free water, being denser, sinks to the bottom. |

Prior to collecting the sample, technicians must perform a crucial preparatory step: flushing the sample valve. It is standard practice to flush 2 to 4 quarts of waste oil through the sample valve to clear any stagnant fluid or debris that may have accumulated in the valve and line, ensuring the collected sample is fresh and representative of the bulk fluid.

Specific Gravity of Common Transformer Insulating Fluids

The table below lists the specific gravity ranges for common transformer insulating fluids encountered in the field, along with the corresponding recommended sampling location based on the SG Rule of Thumb.

| Fluid | Specific Gravity (SG) Range | Recommended Sample Location |

| Askarel (PCB) | 1.56–1.38 | Top |

| Water | 1.00 | N/A |

| Silicone | 0.98–0.834 | Bottom |

| FR3 | 0.92 | Bottom |

| BioTemp | 0.91 | Bottom |

| Mineral Oil | 0.89 | Bottom |

Exceptions and Special Considerations

While the specific gravity rule provides a reliable guideline, there are instances where the sampling point may deviate from the standard protocol.

One common exception occurs with older transformers that lack a dedicated drain valve. In such cases, access for sampling is typically obtained by removing the transformer’s top cover. Furthermore, the optimal sampling point can change over the transformer’s operational life, particularly after a retrofill procedure—the replacement of one insulating fluid with another (e.g., replacing Askarel with Silicone). Technicians must be aware of the current fluid type and its specific gravity to determine the correct sampling location post-retrofill.