ASTM Standard Test Methods for Transformer Insulating Oil

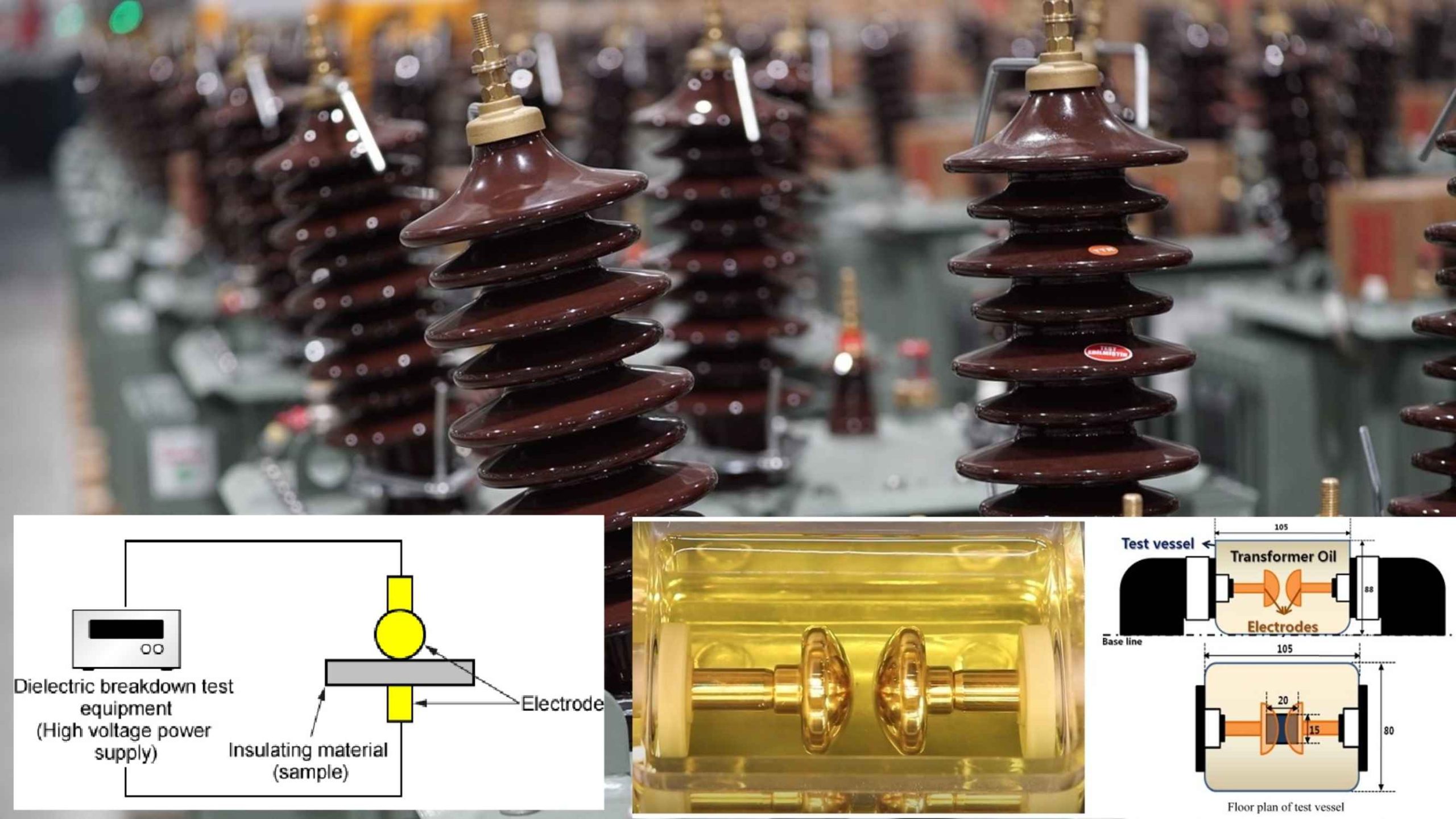

The insulating fluid is arguably the most critical component of a liquid-filled electrical apparatus, often referred to as its “lifeblood.” Regular sampling and laboratory analysis of this fluid provide invaluable insight into the equipment’s internal condition, often detecting issues that conventional electrical tests may miss. The American Society for Testing and Materials (ASTM) develops and maintains the standards that support the quality, distribution, and in-service monitoring of these insulating liquids.

The specific set of tests and acceptable parameters for an insulating oil sample must be tailored to the apparatus type, voltage class, fluid chemistry, and service age. The following is a detailed overview of the key ASTM standard test methods used to assess the condition of transformer insulating oils.

Summary of Key ASTM Test Methods

| Test Name | ASTM Standard | Typical Units | Property Assessed | Significance |

| Dielectric Breakdown Voltage | D877 / D1816 | kV | Electrical Strength | Measures the oil’s ability to withstand electrical stress. |

| Power Factor | D924 | % | Dielectric Losses | Indicates contamination or deterioration causing energy dissipation. |

| Resistivity | D1169 | Ohm-cm | Electrical Insulating Properties | Measures the concentration of conductive contaminants (free ions). |

| Moisture (Water) Content | D1533 | ppm | Chemical Contamination | Lowers dielectric strength and accelerates insulation degradation. |

| Neutralization (Acid) Number | D974 | mg KOH/g | Chemical Degradation | Measures the concentration of acidic byproducts from oxidation. |

| Interfacial Tension | D971 | mN/m | Chemical Contamination | Measures the presence of soluble contaminants and oxidation products. |

| Dissolved Gas Analysis (DGA) | D3612 | ppm | Internal Faults | Identifies fault gases (e.g., H2, CO, C2H2) indicating thermal or electrical stress. |

| Furanic Compounds | D5837 | ppb | Solid Insulation Degradation | Determines the degradation level of cellulosic materials (paper, pressboard). |

| Kinematic Viscosity | D445 | mm²/s | Physical Flow Characteristics | Assesses the oil’s ability to circulate and transfer heat effectively. |

| Flash Point, Fire Point | D92 | °C | Volatility and Fire Risk | Indicates the minimum temperature for flammable vapor formation. |

Electrical Property Tests

These tests evaluate the oil’s ability to act as an electrical insulator, its primary role within a transformer.

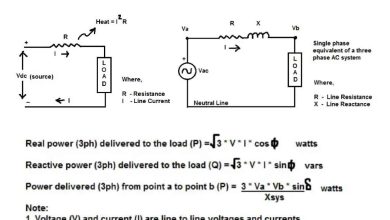

Dielectric Breakdown Voltage (ASTM D877 and D1816)

- Units: Kilovolts (kV)

- Purpose: This test measures the voltage level at which the insulating oil fails electrically. This value is a direct indicator of the presence of contaminants, most commonly moisture and particulate matter, which reduce the oil’s insulating capability.

D877 vs. D1816:

- D877 uses standard flat-disk electrodes.

- D1816 uses VDE (Verband der Elektrotechnik) mushroom-shaped electrodes. This method is often considered more sensitive due to the geometry of the electrodes and may be run at different gap settings (1 mm or 2 mm). New mineral oil should typically exhibit a minimum dielectric strength of 35 kV.

Power Factor (ASTM D924)

- Units: Percent (%)

- Purpose: The power factor test indicates the dielectric losses within the oil, which is the energy dissipated as heat when the oil is subjected to an alternating current (AC) field.

- Significance: A high power factor suggests the presence of contamination or deterioration products, as these materials increase the oil’s conductivity and energy loss. The power factor is mathematically defined as the cosine of the phase angle between the applied AC voltage and the resulting current. For new mineral oil, the power factor should not exceed 0.05% at 25°C.

Resistivity (ASTM D1169)

- Units: Ohm-centimeters (Ohm-cm)

- Purpose: This test directly measures the electrical insulating properties of the oil.

- Significance: A low resistivity indicates a high concentration of free ions and ion-forming particles in the oil, indicating a high concentration of conductive contaminants. Conversely, high resistivity is desirable, as it signifies superior insulating performance.

Chemical Property Tests

These tests assess the chemical condition of the oil, including the presence of harmful byproducts and contaminants.

Moisture (Water) Content (ASTM D1533)

- Units: Parts per million (ppm)

- Purpose: Measures the concentration of water dissolved or suspended in the oil.

- Significance: Moisture is highly detrimental to the transformer’s insulation system. It significantly lowers the oil’s dielectric strength and accelerates the degradation of the solid paper insulation. For mineral oil, a generally accepted maximum moisture content is often set around 35 ppm. It is important to note that this test measures the water in the oil, not the water absorbed by the paper insulation.

Neutralization (Acid) Number (ASTM D974)

- Units: Milligrams of Potassium Hydroxide per gram of oil (mg KOH/g)

- Purpose: Measures the content of acidic compounds formed by oil oxidation and contamination. New transformer oils are practically acid-free.

- Significance: The test determines the amount of potassium hydroxide (KOH) required to neutralize the acid in one gram of oil. High acid numbers (typically above 0.10 mg KOH/g) indicate severe oil degradation, which can lead to sludge formation and corrosion of internal metal components.

Interfacial Tension (IFT) (ASTM D971)

- Units: Millinewtons per meter (mN/m)

- Purpose: Measures the force required to pull a ring of platinum wire from the interface between the oil and water.

- Significance: IFT is a sensitive indicator of the presence of soluble contaminants and oxidation products in the oil. A decreasing IFT value directly correlates with an increase in these polar contaminants, signaling the onset of oil deterioration.

Oxidation Inhibitor Content (ASTM D2668)

- Units: Percent (%)

- Purpose: Measures the concentration of antioxidant additives, such as 2,6-ditertiary-butyl paracresol and 2,6-ditertiary-butyl phenol, which are added to new oil to protect against oxidation.

- Significance: In used oil, this test determines the amount of inhibitor remaining. A low concentration indicates that the oil’s natural resistance to oxidation is depleted, making it vulnerable to rapid degradation.

Polychlorinated Biphenyls (PCB) Content (ASTM D4059)

- Units: Parts per million (ppm)

- Purpose: Detects the concentration level of Polychlorinated Biphenyls (PCBs) in the transformer oil, typically using gas chromatography.

- Significance: This test is crucial for environmental and regulatory compliance, as PCBs are persistent organic pollutants. The test also applies to the determination of PCBs present in mixtures known as askarels.

Fault and Degradation Analysis

These specialized tests are used to diagnose specific internal conditions and the degradation of solid insulation.

Dissolved Gas Analysis (DGA) (ASTM D3612)

- Units: Parts per million (ppm)

- Purpose: Identifies and quantifies the various fault gases (e.g., Hydrogen, Methane, Ethane, Ethylene, Acetylene, Carbon Monoxide, Carbon Dioxide) dissolved in the insulating oil.

- Significance: Different gases are generated by specific types of thermal and electrical stresses (e.g., overheating, partial discharge, arcing) occurring within the transformer. DGA is the earliest and most effective method for detecting incipient internal faults.

Furanic Compounds (ASTM D5837)

- Units: Parts per billion (ppb)

- Purpose: Determines the presence of furanic compounds, which are degradation byproducts of cellulosic materials (paper, pressboard, cotton) used for solid insulation. Measurements are typically made using High-Performance Liquid Chromatography (HPLC).

- The concentration of furanic compounds is a direct measure of the degree of aging and remaining life of the transformer’s solid insulation.

Dissolved Metals (ASTM D7151)

- Units: Micrometers (µm)

- Purpose: Identifies dissolved metals that may originate from overheating or arcing, as well as a portion of particulate metals resulting from mechanical wear.

- Significance: Measured by Inductively Coupled Plasma Atomic Emission Spectrometry (ICP-AES), the presence of specific metals (e.g., copper, iron) can pinpoint the location and nature of internal wear or fault conditions.

Physical Property Tests

These tests ensure the oil maintains the necessary physical characteristics for cooling and circulation.

Kinematic Viscosity (ASTM D445)

- Units: Square millimeters per second (mm²/s)

- Purpose: Measures the oil’s resistance to flow. The measurement is based on tracking the liquid’s flow time through a calibrated glass capillary.

- Significance: Viscosity is critical for the oil’s ability to circulate and transfer heat effectively. Temperature is the most important factor influencing viscosity, and changes in viscosity can indicate contamination or excessive thermal stress.

Pour Point (ASTM D97)

- Units: Degrees Celsius (°C)

- Purpose: Indicates the lowest temperature at which the insulating oil will still flow under specified conditions.

- Significance: This test is particularly important for transformers operating in cold climates to ensure the oil remains sufficiently fluid to circulate and serve its dual roles as an insulating and cooling medium.

Flash Point and Fire Point (ASTM D92)

- Units: Degrees Celsius (°C)

- Purpose: Measures the minimum temperature at which the heated oil gives off sufficient vapor to form a flammable mixture with air (Flash Point) and the temperature at which it sustains burning (Fire Point).

- Significance: These points indicate the insulating oil’s volatility and are a key factor in assessing the apparatus’s fire safety risk.

Color (ASTM D1500) and Visual Examination (ASTM D1524)

- Units: Color (0-5 scale); Visual (Bright, dark, clear of particles, etc.)

– Purpose:

- Color (D1500): Compares the oil’s color to a series of color standards and assigns a numerical value.

- Visual (D1524): Involves passing a beam of light through the oil to determine transparency and identify foreign matter.

- Significance: Noticeable darkening of the oil (D1500) or poor transparency/cloudiness/foreign particles (D1524) can indicate contamination, excessive thermal aging, or internal arcing.

Relative Density (Specific Gravity) (ASTM D1298)

- Units: Numerical (unitless)

- Purpose: Determines the density of the transformer oil relative to water at a reference temperature, typically using a hydrometer.

- Significance: A high specific gravity indicates the oil’s ability to suspend water. In extremely cold climates, this value can be used to determine whether, if formed, ice would float on the oil, a critical safety consideration.

Conclusion

A comprehensive oil testing program, built upon the rigorous standards established by ASTM, is essential for effective transformer asset management. By monitoring the electrical, chemical, and physical properties of the insulating fluid, operators can proactively diagnose incipient faults, assess the remaining life of the insulation system, and ensure the long-term reliability and safety of their electrical infrastructure.