Transformer Cooling Systems: Principles, Classifications, and Operational Imperatives

1. The Criticality of Transformer Cooling

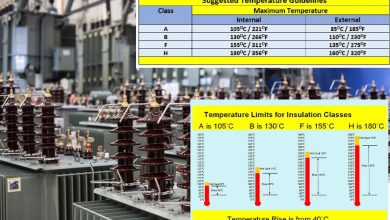

Effective thermal management is paramount to the operational longevity and reliability of power transformers. The primary source of heat generation is copper losses (I²R losses) in the windings and core. Failure to adequately dissipate this heat leads to a continuous rise in internal temperature, which can severely compromise the transformer’s insulation system. A critical rule of thumb in transformer design and operation is that an increase of just 10°C above the rated operating temperature can halve the transformer’s service life. Consequently, a thorough understanding of cooling methodologies and the ability to detect system anomalies are essential for maintaining transformer health.

Transformer nameplates, as required by ANSI and IEEE standards, must clearly display the cooling class, which designates the type of cooling system employed.

2. Dry-Type Transformer Cooling Systems

Dry-type transformers use air as the primary cooling medium, with coils exposed to ambient conditions. Cooling relies fundamentally on natural convection, where heat generated by the coils creates convection currents that draw cool air across the windings. Louvers or screened openings are strategically incorporated into the enclosure to direct this airflow. To enhance cooling capacity, fans are frequently used to introduce forced airflow. This forced cooling can increase the transformer’s kVA rating by up to 33% compared to an equivalent self-cooled design.

Operational and Maintenance Imperatives

Maintaining the efficiency of dry-type cooling systems requires strict adherence to operational guidelines:

•Cleanliness: Enclosures and cooling surfaces must be kept clean. The accumulation of dirt and dust acts as an insulator, impeding heat transfer and causing a gradual, often unnoticed rise in operating temperature and a reduction in service life.

•Clearance: The area surrounding the transformer must remain clear. Placing objects near or against the enclosure restricts the necessary heat transfer and airflow.

Dry-Type Cooling Classifications

Cooling classifications for dry-type transformers are governed by the ANSI/IEEE standard C57.12.01 . Common examples are summarized in the table below.

| Designation | Cooling Mechanism | Description |

| AA | Ventilated, Self-Cooled (Natural Air) | Air circulation is achieved solely through natural convection. Cooler air enters lower ports, rises past the windings as it heats, and exits through upper ventilation ports. No fans or external radiators are typically used. |

| AFA | Forced Air-Cooled | Cooling is achieved by the forced circulation of air via fans. These transformers typically have fan inlets and outlets only, with no provisions for natural air circulation. |

| AA/FA | Self-Cooled / Forced Air-Cooled | Dual-rated transformer. It operates as AA (self-cooled) under normal conditions, with fans providing additional forced-air cooling (FA) when the temperature reaches a pre-set value. This provides a dual load rating. |

| ANV | Self-Cooled, Non-Ventilated | No ventilation ports or fans. Cooling occurs by natural circulation of air around the sealed enclosure. The enclosure is not hermetically sealed but is designed to prevent intentional ingress/egress of outside air. External fins may be attached to increase surface area. |

| GA | Gas-Sealed, Self-Cooled | The core and coils are sealed within the enclosure with an internal gas (e.g., nitrogen, SF6) to provide high dielectric strength and efficient heat removal. Cooling is by natural air circulation around the outside of the hermetically sealed enclosure, often aided by external fins. |

3. Liquid-Cooled Transformer Cooling Systems

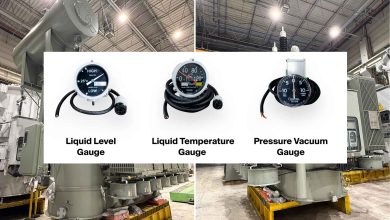

Liquid-cooled transformers feature the core and coils immersed in an insulating liquid, typically mineral oil, which serves the dual purpose of providing electrical insulation and removing heat. The condition of the insulating liquid is critical. As transformer oil degrades due to aging and moisture ingress, its insulating and cooling properties diminish. Therefore, periodic sampling and analysis of the transformer oil, in accordance with ASTM insulating oil test methods, is essential for predictive maintenance.

Modern Cooling Class Designations (IEEE C57.12.00-2000 and Later)

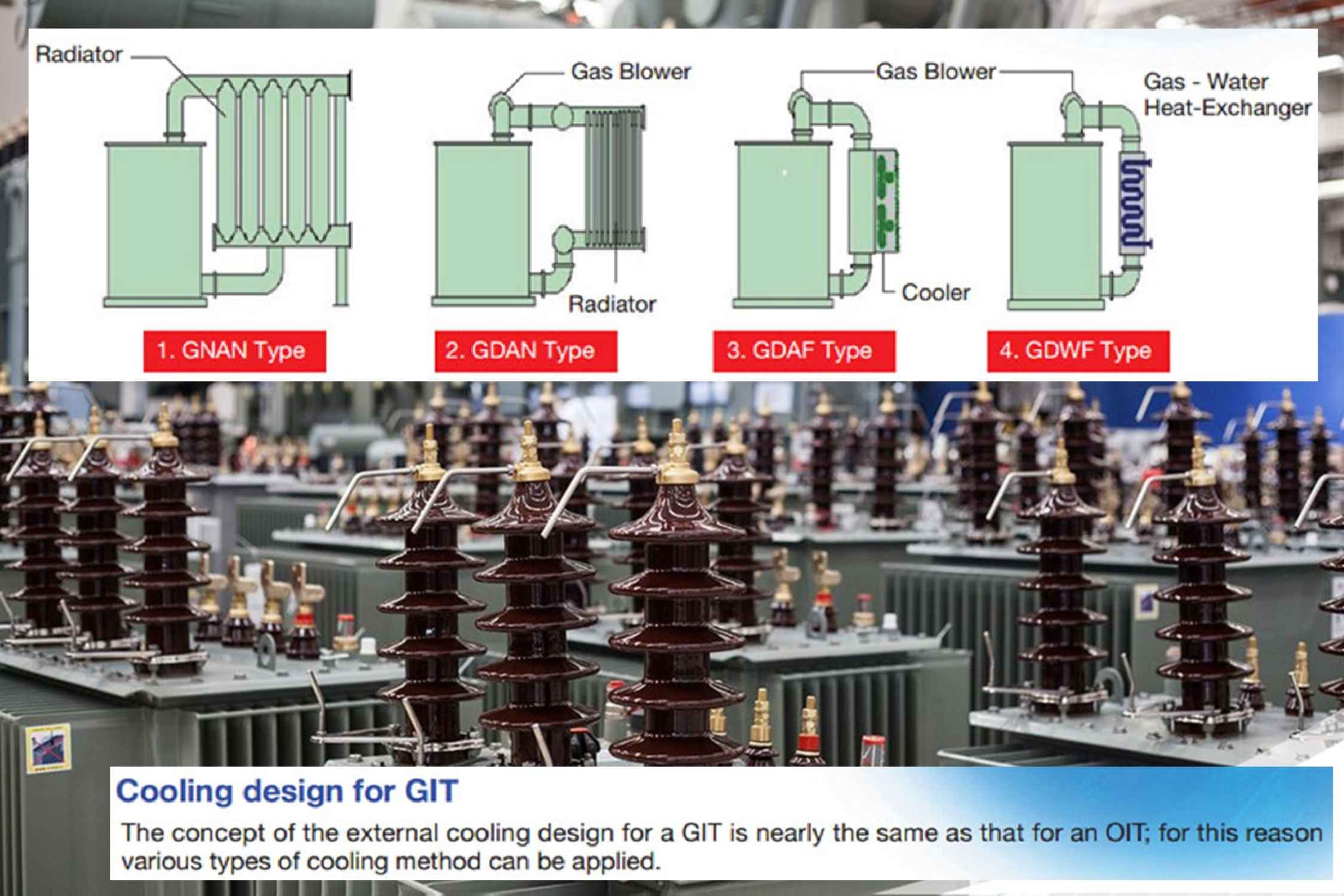

In the United States, the cooling classification system for liquid-cooled transformers was standardized with the adoption of the four-letter designation in IEEE Standard C57.12.00-2000 . This system provides a precise description of the cooling process by defining four key elements:

| Letter Position | Description | Common Designations |

| First Letter | Internal Cooling Medium (in contact with the windings) | O: Mineral oil or synthetic liquid (fire point < 300°C) |

| K: Insulating liquid (fire point > 300°C) | ||

| L: Insulating liquid (no measurable fire point) | ||

| G: Gas insulated | ||

| Second Letter | Internal Circulation Mechanism | N: Natural convection flow through cooling equipment and windings |

| F: Forced circulation through cooling equipment (pumps), natural convection in windings (non-direct flow) | ||

| D: Forced circulation through cooling equipment, directed into at least the main windings | ||

| Third Letter | External Cooling Medium | A: Air |

| W: Water | ||

| Fourth Letter | External Circulation Mechanism | N: Natural convection |

| F: Forced convection |

Examples of Modern Liquid-Cooled Classes

The four-letter system allows for the precise classification of various cooling configurations, often corresponding to multiple load ratings.

| Modern Designation (Post-2000) | Historical Designation (Pre-2000) | Description |

| ONAN | OA | Oil Natural, Air Natural. Oil-immersed, self-cooled. Cooling is achieved by natural circulation of the oil inside the tank and natural circulation of air around the outside enclosure. External fins or radiators may be attached. |

| ONAN/ONAF | OA/FA | Oil Natural, Air Natural / Oil Natural, Air Forced. Dual-rated. Operates as ONAN, with the addition of fans (Forced Air) on the radiators to provide a higher load rating when activated automatically by temperature. |

| ONAN/ONAF/ONAF | OA/FA/FA | Triple-rated. Similar to ONAN/ONAF, but with two distinct groups of fans, providing three load ratings corresponding to self-cooling, one stage of forced air, and two stages of forced air. Oil flow remains by natural convection. |

| ONAN/ONAF/OFAF | OA/FA/FOA | Triple-rated. Includes self-cooling (ONAN), forced air-cooling (ONAF), and a third stage with Forced Oil (pumps) and Forced Air (fans) cooling. Fans and pumps are typically wired to start automatically. |

| ONWF | OW | Oil Natural, Water Forced. Oil-immersed, water-cooled. Cooling is achieved via an oil/water heat exchanger (radiator). Cooling water is pumped (Forced) through the exchanger, but the oil flows only by natural convection. |

| OFAF | FOA | Oil Forced, Air Forced. Single-rated. Cooling is achieved by pumping oil (Forced Oil) through a radiator, while air is simultaneously forced over the cooling surface by fans (Forced Air). |

| OFWF | FOW | Oil Forced, Water Forced. Single-rated. Cooling is achieved by an oil/water heat exchanger, typically mounted separately. Both the transformer oil and the cooling water are actively pumped (Forced) through the heat exchanger. |

Historical Cooling Class Designations (Before 2000)

For reference, the table below summarizes the historical two-letter designations used before the adoption of the modern four-letter system.

| Letter | Designation |

| A | Air (Natural Convection) |

| FA | Forced Air (Fans) |

| O | Oil (Natural Convection) |

| FO | Forced Oil (Pumps) |

| G | Gas |

| W | Water/Oil Heat Exchanger |

References

[1] ANSI/IEEE Standard C57.12.01 and C57.12.00-2000 (Standards for Transformers)