The Unsung Hero: Why the Auxiliary Power System is the Silent Backbone of Every Plant

No alarms sound for it. No flashy control panels celebrate its operation. Yet, in any power plant or critical industrial facility, nothing moves, nothing generates, and nothing operates without it. This is the auxiliary power system—the silent, vigilant backbone that makes all primary production possible.

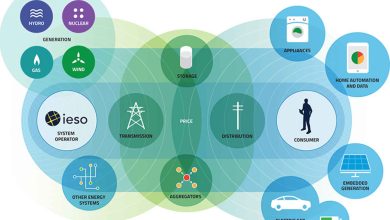

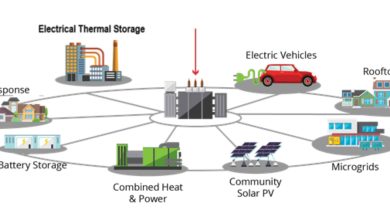

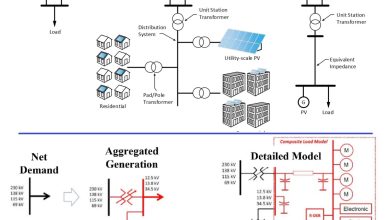

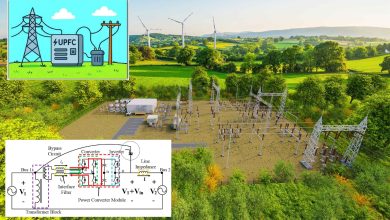

While the main turbine may roar with the effort to produce megawatts for the grid, it is the auxiliary system that quietly ensures every critical support function remains operational. It powers the lubrication pumps that prevent catastrophic bearing failure, drives the cooling fans that manage operational temperatures, energizes the control panels and protection circuits that govern safety, and supports a host of other essential auxiliaries. Its role is not to produce power for export, but to make the very production of power possible.

The High Cost of Common Oversights

Neglecting this critical system is a gamble with multimillion-dollar stakes. Here are the often-overlooked truths that can mean the difference between reliability and ruin:

🔹 Main Generation Alone Is Not Enough

The most advanced turbine or generator is merely a static piece of machinery without its auxiliary systems. These systems feed the essential equipment that allows the primary unit to function safely and efficiently.

🔹 Black Start Begins with Auxiliaries, Not Turbines

The process of restarting a plant from a total shutdown—a “black start”—relies entirely on the auxiliary power system. It must first energize the equipment needed to safely spin up, control, and synchronize the main generator.

🔹 Redundancy Only Works If Tested

Standby generators, Uninterruptible Power Supplies (UPS), batteries, and backup feeders are standard. However, untested redundancy is ineffective redundancy. These systems must be proven capable of carrying real operational loads under realistic conditions, not just idle on paper.

🔹 Voltage Dips and Neglected Feeders Cause Silent Failures

Auxiliary systems power sensitive controls, variable frequency drives, and protection relays. Voltage transients or degraded feeder health can cause these components to fail quietly, with the root cause often mistakenly attributed to other, unrelated systems.

🔹 Maintenance Matters—Deeply

The devil is in the details. A single loose connection, an aging battery bank, a dirty breaker contact, or a missed calibration can cascade into hours or days of unplanned downtime, resulting in massive production losses and costly emergency repairs.

A Call for Shared Vigilance

The reliability of an auxiliary power system is a testament to diligent engineering, proactive maintenance, and hard-earned operational wisdom, for those who work with these systems daily—engineers, technicians, maintenance planners—your insights are invaluable.